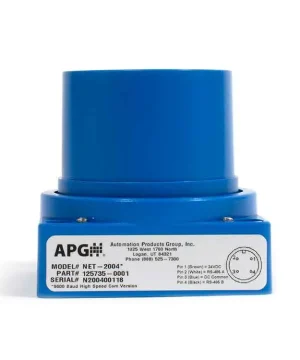

Web Enabled Ultrasonic Level Sensor and Modbus Controller

LOE

Web-Enabled Ultrasonic Level Sensor and Modbus Controller

The LOE Web-Enabled Ultrasonic Level Sensor and Modbus Controller is designed for remote level measurement, providing internet-based monitoring for up to 10 APG Modbus level sensors. Featuring web-based programming, the LOE liquid level sensor allows users to adjust settings remotely, ensuring seamless integration into various industrial applications.

Engineered for cost-effective and reliable performance, this sensor simplifies industrial level measurement with Modbus RS-485 and Ethernet TCP/IP connectivity.

- Affordable Monitoring: Cost-effective remote level monitoring

- Easy Setup: Web-based programming for easy setup

- Real-Time Insights: Intuitive online interface with real-time monitoring

- Smart Alerts: Data logging, email, and SMS alerts

- Multi-Sensor Support: Compatible with up to 10 APG Modbus level sensors

- Precision Sensing: Accurate, high-resolution ultrasonic measurement

- Rugged Protection: Durable housing with IP65 protection rating

- Seamless Connectivity: Modbus RS-485 and Ethernet TCP/IP connectivity

- Power-Efficient: Power-over-Ethernet (PoE) option available

Select an option to begin configuring.