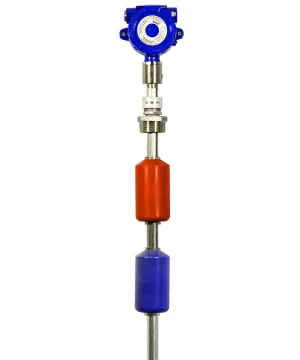

Flexible PVDF Continuous Level Sensor

MPI-F PVDF

Reliable, Accurate Level Monitoring with the MPI-F PVDF Continuous Float Sensor.

The MPI-F/K Continuous Float Level Sensor from APG ensures precise liquid level monitoring in demanding industrial applications. Built with corrosion-resistant PVDF tubing, it simplifies installation in tall storage tanks while maintaining its Class I, Div 1 Intrinsically Safe rating. Designed for water, wastewater, chemical, oil and gas, and industrial effluent applications, the MPI-F/K provides continuous, accurate level measurement with minimal maintenance.

- Flexible Installation: 5/8” flexible PVDF tubing allows for easy setup without large cranes.

- Modbus Compatibility: RS-485 Modbus RTU output integrates seamlessly with PLC and control systems.

- Remote Monitoring: Works with Settler and Explorer for remote monitoring.

- Reliable in Harsh Environments: NEMA 4X/IP66-rated for protection against dust, water, and extreme temperatures (-40° to 185°F).

- Precise Measurements: ±0.05% FS or ±1 mm accuracy, ideal for oil/water interface monitoring, thick fluids, and industrial processes.

Select an option to begin configuring.