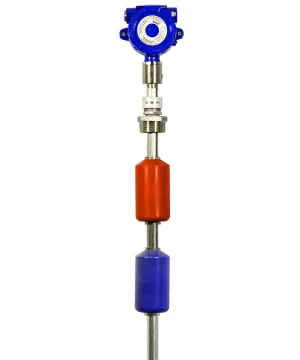

Intrinsically Safe, Titanium Stem Magnetostrictive Float Level Transmitter

MPI-T

Big Time Anti-Corrosion and HazLoc Ratings For Big Applications

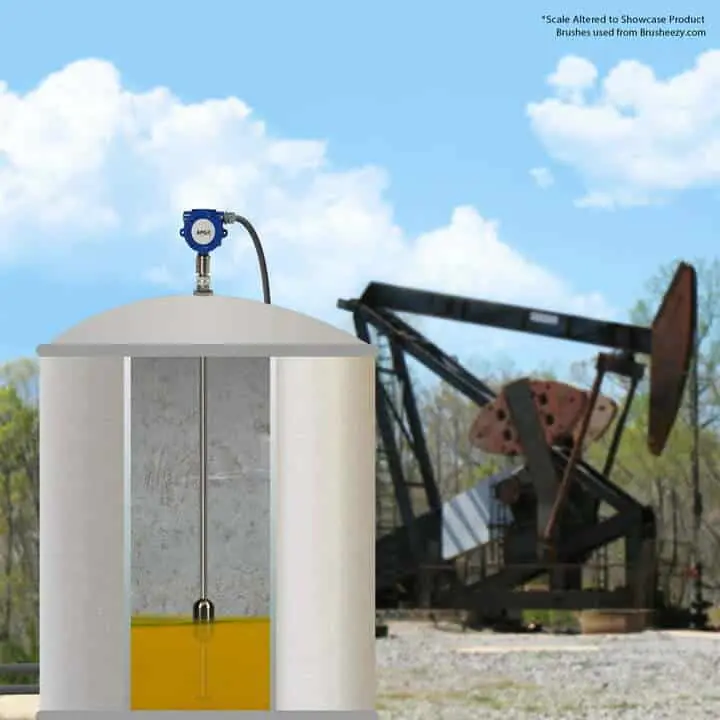

The MPI-T Intrinsically Safe Titanium Stem Magnetostrictive Float Level Transmitter is designed for accurate liquid level measurement in corrosive and hazardous environments. Engineered to withstand Hydrogen Sulfide (H2S) and other aggressive chemicals, the MPI-T ensures reliable performance in industrial applications such as water treatment, chemical processing, pulp and paper, and marine environments.

- Intrinsically Safe: Intrinsically Safe for use in hazardous locations (Class I, Division 1, Zone 0)

- Durable Construction: Corrosion-resistant titanium stem and float for extreme environments

- Seamless Compatibility: RS-485 Modbus RTU output for seamless integration with any Modbus controller

- Remote Monitoring: Compatible with LOE Server and RST-5003 for remote monitoring

- Accurate Measurement: Highly accurate level measurement with ±0.04 in. resolution

Select an option to begin configuring.