We’ve been quietly working on expanding our sensors that have a Modbus output. These updates have helped a lot of customers do more with their sensors. Well, we thought it was time to break the silence and announce it to the world.

We’ve been quietly working on expanding our sensors that have a Modbus output. These updates have helped a lot of customers do more with their sensors. Well, we thought it was time to break the silence and announce it to the world.

Modbus is nothing new – not for us, and certainly not for the industry – but it is an improvement on a few of our level and pressure sensors that we wanted to bring to your attention. Our Modbus line-up has gotten bigger, and includes ultrasonic sensors, magnetic level probes, submersible pressure sensors, pressure transducers, and a compact display.

So chances are, if you’re looking for a level or pressure sensor with Modbus, we’ve got one for you.

Modbus is among the most popular industrial protocols being used today. It is easy to deploy, simple, universal, and free of royalty fees. Even though it has been around for more than 30 years, it remains to be the protocol of choice for industrial instrumentation manufacturers and integrators.

Despite its popularity and longevity, we still have a lot of customers who have never used it. So if you haven’t considered using it before for tank level monitoring, we recommend you think again.

Developed in 1979 by Modicon (now Schneider Electric), Modbus was made to communicate with multiple devices over a single twisted pair wire. Originally, Modbus ran over RS232 but was soon adapted to run over RS485 for faster speeds and longer distances. After that, Modbus quickly became very popular in the automation industry.

Modicon eventually released the protocol to the public and it is now managed by a few organizations, MODBUS-IDA (www.modbus.org) being the largest.

Modbus is made up of Severs and Clients. The device that requests information is called the Modbus Server, and the devices that supply the information to the Server are called Modbus Clients. Typically, a programmable logic controller (PLC), or human interface device, is the Server while field sensors are clients. Clients are connected to the server via a multi-drop configuration (daisy-chain). Only the server can initiate communication while the clients can only respond.

Modbus is made up of Severs and Clients. The device that requests information is called the Modbus Server, and the devices that supply the information to the Server are called Modbus Clients. Typically, a programmable logic controller (PLC), or human interface device, is the Server while field sensors are clients. Clients are connected to the server via a multi-drop configuration (daisy-chain). Only the server can initiate communication while the clients can only respond.

Each server can have up to 247 clients, each with a unique address of 1 to 247. Each client has registers where information is stored. This information can be anything such as temperature, pressure, or level values.

So to communicate with the client devices you will use the server (your PLC or other device) to send code to a client. A line of code specifies which client the message is supposed to go to and which register to write to or read from.

Modbus comes in a variety of versions. The two most common are Modbus RTU and Modbus TCP/IP.

The difference between the two is simple. Modbus TCP/IP utilizes IP addresses. To do this, additional code is added so that information can be transmitted over a network (TCP/IP) instead of serial lines (RTU). To put it simply, Modbus TCP/IP acts as a wrapper and has a Modbus RTU message inside of it.

Modbus didn’t become the most popular industrial automation protocol for nothing. From the very beginning, Modbus was created with industrial applications in mind. It was designed by a group of people that had a real understanding of the challenges being faced in the automation industry. A good example of this is the wiring scheme.

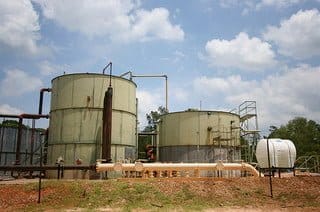

The multi-drop configuration keeps costs down by using inexpensive twisted pair cable, and reducing the amount of cable needed for installation. It also simplifies the installation process (again, less cable and connections to worry about). When it comes to tank level monitoring, the advantage of a multi-drop configuration can be fully appreciated at a tank farm.

A lot of wireless tank monitoring sensors have a built-in cellular modem. While this solution is convenient, it may not always be the most efficient. Using one of these sensors on each tank at a tank farm is wasteful. You are paying for each tank to have its very own gateway to the internet. On the other hand, with Modbus, a Server gateway device (this can be wireless) could be used to connect all of the Client sensors to the internet. Now you are paying for only one internet connection to monitor multiple tanks.

So you may be asking yourself: How difficult is this to integrate? The answer is that it is not. Most PLCs and network devices for the industrial automation industry support Modbus. Since it is an open protocol there is no shortage on the availability of Modbus supported equipment. This way you can integrate equipment from a variety of vendors to create the best tank level monitoring system for your unique application.

Furthermore, since Modbus is an open protocol, there is a large number of online resources that offer free help in writing your own code if you wish to do so. A good example of this is Simply Modbus (www.simplymodbus.ca). If you are not a programmer, don’t worry, you can buy an off the shelf tank level monitoring solution that takes advantage of Modbus from a variety of vendors that doesn’t require any programming.

Finally, there are no royalty fees with Modbus since it is an open protocol. This means that when you buy a device that supports Modbus, none of that cost is being allocated to pay a royalty fee to the developer of the protocol. This is not the case with many of the other popular protocols being used today.

Many professionals, even after working with the new industrial protocols, come back to Modbus over and over because it is free, universal, and easy to use. So if you haven’t tried Modbus for remote tank level monitoring, you might want to reconsider.

Contact us if you have any questions about using Modbus level or pressure sensors.