Shunt Cal, short for Shunt Calibration, is a method for determining the full-scale output of a pressure transducer by electrically simulating a full-scale load. Either a shunt resistor is applied to the transducer circuit, or voltage is applied to an ancillary circuit designed to generate a full-scale output. That output can then be measured precisely to calibrate the control system’s reading of the pressure transducer. At Automation Products Group, Inc. (APG), we’ve consulted with our experts to provide this guide for all things Shunt Cal.

The Working Principle

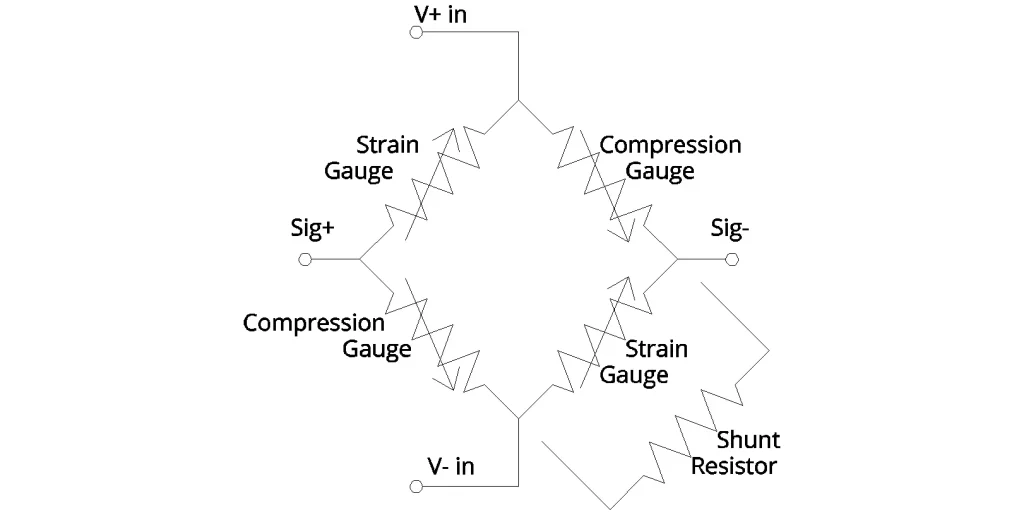

Shunt Cal works on piezoresistive strain gauge-type pressure transducers. Four of these small gauges are connected in Wheatstone bridge formation. The gauges convert changes in mechanical strain and compression due to pressure into changes in electrical current. The strain gauges produce minimal current at minimum pressure, while allowing peak current flow at full-scale pressure.

For simple, unamplified signals, Shunt Cal simulates maximum compression by placing a known resistor in parallel with one of the strain gauges (i.e., shunting the gauge), driving the output to 80% of maximum. This method is quick, relatively easy, and doesn’t significantly increase the manufacturing cost. Sizing the resistor is a matter of math, but after that, the primary hurdle is switching the resistor in and out of shunt position.

But moving conductive pieces right on the gauge is hurdle. Moving parts are prone to failure, and placing conductive paths near the sensor’s most sensitive electronic part risks introducing noise and bias into the measurement signal.

Conditioning Circuitry Shunt Calibration

Transducers with signal conditioning circuitry are also used to produce Shunt Cal. As part of the conditioning, an ancillary circuit can be added that produces a full-scale output. How that’s achieved depends on the design of the signal conditioning circuitry.

A sensor using conditioning circuitry for Shunt Cal can cost more than one using a shunt resistor. But the trade-offs are substantial: greater reliability, and a full-scale Shunt Cal, rather than just 80%. Without the moving resistor, a sensor with conditioning Shunt Cal doesn’t have the breakdown concerns or noise and bias issues that a sensor with standard Shunt Cal would have. The full-scale output is always more helpful for calibration than 80% of full-scale.

Application And Usefulness

There are two primary purposes for using Shunt Cal.

- Calibrating the control system equipment communicating with the transducer. It’s important to know the transducer’s full-scale output. Performing a Shunt Cal allows compensation for the load resistance of the cable between transducer and controller. With unamplified signals, the difference between 19.925 mA and 20.125 mA can be significant. Shunt Calibration helps accurately set the control system.

- Confirming the transducer functions properly. In this scenario, Shunt Cal is used for troubleshooting the transducer. If the transducer’s output is significantly short of 20 mA with Shunt Cal applied, the system needs to be adjusted.

APG and Shunt Cal

At APG, we offer Shunt Cal capabilities on our hammer union pressure transducers. Our other pressure transducers can be calibrated and tested using full-scale pressure on a comparator. Because of their size and pressure range, hammer union pressure transducers are difficult to bench test. Thus, offering Shunt Cal capabilities provides a safe and easy method for testing.

If you have any questions about Shunt Cal or our hammer union pressure transmitter, contact us today. We’ll discuss your application and point you in the right direction.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.