Normally, I don’t see our waste and wastewater monitoring in action. As a technical writer, most of my time is spent at a computer, whether I'm writing blog posts or editing datasheets and manuals. And while I do write quite a bit about how APG's sensors can be used and which sensors are the most advantageous in various settings, my experience is almost all theoretical. Until Kurtis Williams with Logan City Water and Waste Water agreed to show me where and how they use APG's sensors.

Our first stop was a well house. Here two PG10s with remote transducers are used to monitor system pressure. The PG10s show percent-of-full-scale pressure on their bar graphs and have 4-20 mA outputs connected to the utility’s SCADA system. Although the SCADA system has an HMI screen in the well house, the PG10s allow utility workers to access the pressure readings from the two transducers without logging into the SCADA system.

The following two stops were at wastewater lift stations. At each station, a pair of PT-500 submersible pressure transducers with cages is used to control the main pumps. As with the PG10s in the well house, the PT-500s have a 4-20 mA output for direct integration into the SCADA system. In the sewage pits, PVC piping is used in a fashion similar to stilling wells. But, instead of eliminating turbulence-based chatter on the PT-500s' readings, the PVC piping keeps the submersible pressure transducers in place, preventing the pumps from damaging drifting sensors. At the first lift station, the SCADA access screen is in a separate room from the sewage pits (because ewww, stinky). The leads from the PT-500s land on a terminal strip in an enclosure in the control room, allowing the desiccant cartridges for the PT-500s to be easily monitored.

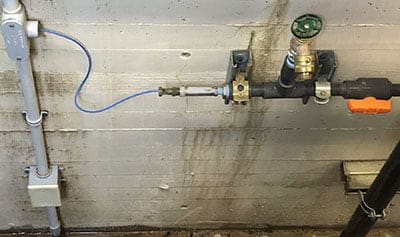

Ancillary piping at the lift stations shows potential for sensor upgrades. For instance, this pressure transducer (which is not an APG PT-L1) and this dial gauge are monitoring the same pressure point. Rather than two separate instruments, a digital pressure gauge with a 4-20 mA output--such as APG's PG5, PG7, or PG10--would combine their functions and offer the additional upgrade of a digital display over the imprecision of a dial gauge.

Discussing displays led us to an unplanned stop at a below-street pressure relief valve (or PRV). On each side of the valve is a pressure transducer with a 4-20 mA output tied to the SCADA system. And that's it. Other than the small dial gauges above the transducers, there are no visible indicators for what's going on in the pipes: no SCADA interface, no display screens, nothing.

So, what kind of displays would work down in a below-street area? What is the best fit? Because the transducers have a 4-20 mA connection to the SCADA system, the easiest solution is to add an LPD Loop Powered Display for each pressure transducer. LPD's can be mounted several ways, come with IP67 plastic or IP68 aluminum housing, and, perhaps most importantly for an area infrequently visited, an on-off button for the display. Another solution would be to mimic the well house setup, with either PGs mounted on the piping (where the current transducers are mounted) or PGs mounted on a wall with remote transducers on the piping. A third option would put large digital DDL displays or explosion-proof digital DDX displays on the wall connected to transducers on the piping. The decision-making process would hinge on the desired level of interaction with the displays (always on, turn on & turn off, or turn on with timed turn off) and the level of protection necessary for the displays (IP/NEMA only, or hazardous location certification).

Two APG PG10 digital pressure gauges mounted on the door of a deep well control cabinet with remote heads on associated piping.

Our fifth stop was another well house. This one also uses remote PG10 displays for transducers on pipes, but with the displays mounted through the face of a control cabinet. The well also uses a PT-500 for depth monitoring (approximately 70 ft of water in a 240 ft well, both easily within the PT-500’s 575 ft max submersible range), and since the water is clean, the protective cage is not necessary. Instead, a plastic nose cone protects the transducer face. This well, along with others throughout the system, had been monitored using an ultrasonic sensor. However, wintertime steam from frigid air meeting the warmer (but still cold!) water and the occasional miscreant's misadventures with soapsuds interfered with accurate level measurement, sometimes resulting in pumps running with no water present. Thus, the utility has replaced the ultrasonics with PT-500 submersible pressure transducers. Vapors and foam do not inhibit the PT-500's accuracy.

Our final stop was a spring water collection point. The site consists of a "spring box," which collects fresh spring water, treatment assembly, which includes adding chlorine for purification, and then a connection to a five-mile, gravity-based line to the utility's distribution network. The spring box is a concrete box with a gravel bottom that filters the spring water from its source. A PT-500 sits on the gravel, measuring the depth of the spring water in the box. Even though the spring box is full of fresh spring water, the PT-500 has a cage on which it rests to protect the diaphragm from the gravel it is resting on. The output of the PT-500 is crucial for maintaining positive pressure in the system, preventing treated water from flowing back into the spring and its overflow into the river a couple of hundred feet away.

The gravel floor of the spring box sits below grade, with the top of the box about a foot above grade. Also below grade, in the equipment house next to the spring box, are the chlorine system pumps. A single APG PT-L1 pressure transducer is used to monitor the line pressure for the chlorine pumps. The PT-L1has a 4-20 mA output to the SCADA system, which has an HMI screen in the above-grade-room in the equipment house. Once again, because the SCADA HMI is in a separate room from the pressure sensor, there's no indication of system status when looking at the pumps. While the potential for escaped chlorine from the system is an important consideration, the chlorine pumps are below grade, and chlorine is heavier than air. So a display mounted sufficiently above grade would be protected from nominal escaped fumes.

Since I don't get to see our sensors "out in the wild" very often, it was good to see some how of our water and wastewater monitoring sensors used by the Logan City utilities and how decisions are being made to choose between available technologies for particular applications. For instance, it's easy to think situations that call for pressure transmitters are entirely separate from conditions where pressure gauges would be appropriate. Instead, I found multiple places where both a local display and a connection to a control network are necessary. And while some customers look for specific control network technology, such as Modbus, others prefer the near-universal ease of use in 4-20 mA sensors. Ultimately, I was reminded that while APG offers many solutions, it is up to each customer to understand their own needs, so that we can find the best solution together.

And speaking of questions, if you’ve got 'em, we’d love to help you find answers. Our sales staff are very familiar with all the application questions, even the ones you haven't thought of yet! They are ready to help you find the perfect sensor type or display for your situation.