Mounting mistakes are one of the most common pitfalls when installing ultrasonic level sensors—but they’re also one of the easiest to avoid. At Automations Products Group, Inc. (APG), we’ve worked with thousands of customers to ensure sensors are installed the right way. This guide walks you through the basics of proper mounting, so your sensor delivers accurate, reliable data—day after day.

Mounting Rules for Ultrasonic Sensors

Whether you’re measuring liquid in a tank, channel, or stream, keep these best practices in mind:

- Keep it perpendicular

The face of the sensor should be directly perpendicular to the target surface. If the sensor is a few degrees off perpendicular can cause the signal to bounce away, resulting in missed or inaccurate measurements. - Avoid obstructions

Mount the sensor in a location that provides an unobstructed column of air from the sensor to the target. Generally speaking, you need a 3–4 foot diameter unobstructed column even at longer ranges. Stilling wells provide a good solution for liquid level applications where an unobstructed path to the target is difficult. - Account for blanking distance

Always mount the sensor above the highest anticipated target level by at least the minimum blanking distance—typically 4–12 inches, depending on the model sensor you are using. This ‘dead zone’ is the space where the sensor can’t detect reliably. - Stay away from fill spouts

Mounting too close to the spout could result in false readings. White noise can also be a problem, as it can interrupt the sound wave. Place the sensor away from the agitation or acoustic interference. - Avoid the center of domed tanks

Avoid mounting the sensor in the direct center of a tank if there’s a domed top. The shape of the top could amplify small undesired signals inside the tank, increasing the chance of echo interference. - Give tank walls some space

If the walls are corrugated or prone to buildup on tank walls, reflections from uneven surfaces can interfere with the return signal. Mount sensors where the signal path stays clean. - Shade outdoor sensors

If the sensor will be mounted outdoors, try to shade the sensor from direct sunlight. This can harm the sensor housing and cause overcompensation for temperature as the sensor heats up.

Mounting Examples in Real Applications

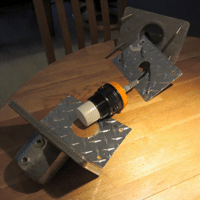

- Boom-Mounted Sensor for Dam Tailwaters

Just south of Cleveland, OH, a team needed to monitor tailwaters at a small dam. They used the LPU-2428 ultrasonic level sensor and built a boom bracket to keep the sensor suspended and perfectly perpendicular to the water’s surface.

Just south of Cleveland, OH, a team needed to monitor tailwaters at a small dam. They used the LPU-2428 ultrasonic level sensor and built a boom bracket to keep the sensor suspended and perfectly perpendicular to the water’s surface.

Rounded edges on the bracket allowed sound waves to pass without reflection or signal trapping—an important detail in ultrasonic mounting.

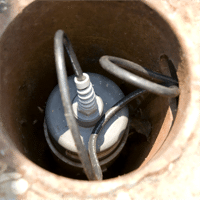

- Stilling Well Installation in Logan, Utah

At a dam near our APG headquarters in Logan, Utah, another team took a different approach. Instead of using a boom to suspend the sensor above the water, they bored a hole through a concrete bridge above the water and installed a stilling well. The stilling well isolated water from surface turbulence, ensuring steady and repeatable readings for irrigation canal monitoring.

At a dam near our APG headquarters in Logan, Utah, another team took a different approach. Instead of using a boom to suspend the sensor above the water, they bored a hole through a concrete bridge above the water and installed a stilling well. The stilling well isolated water from surface turbulence, ensuring steady and repeatable readings for irrigation canal monitoring.

The result? A controlled, consistent surface—perfect for ultrasonic sensing.

Bonus Tip: These rules work for radar sensors, too.

While ultrasonic level sensors rely on sound waves, radar level sensors use electromagnetic waves, which can operate in many adverse environments where ultrasonics struggle. If your application presents challenging environmental conditions, a radar sensor may be the better choice.

Our applications engineers are happy to answer your questions and guide you to the right solution best for your application. Contact us to talk through specific setup and get expert advice tailored to your needs.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.