ENGINEERED JUST FOR YOU

Different Material Options

PE

| 4-20 mA & RS-485 Outputs | |||||

| 76-81 GHz | |||||

| 4º Half Angle Beam | |||||

| Liquid Measure | |||||

| 50 ft. Range |

PVDF

| 4-20 mA & RS-485 Outputs | |||||

| 76-81 GHz | |||||

| 4º Half Angle Beam | |||||

| Liquid Measure | |||||

| 50 ft. Range | |||||

| Chemical Resistant |

| 4-20 mA & RS-485 Outputs | |||||

| 76-81 GHz | |||||

| 4º Half Angle Beam | |||||

| Liquid Measure | |||||

| 50 ft. Range |

| 4-20 mA & RS-485 Outputs | |||||

| 76-81 GHz | |||||

| 4º Half Angle Beam | |||||

| Liquid Measure | |||||

| 50 ft. Range | |||||

| Chemical Resistant |

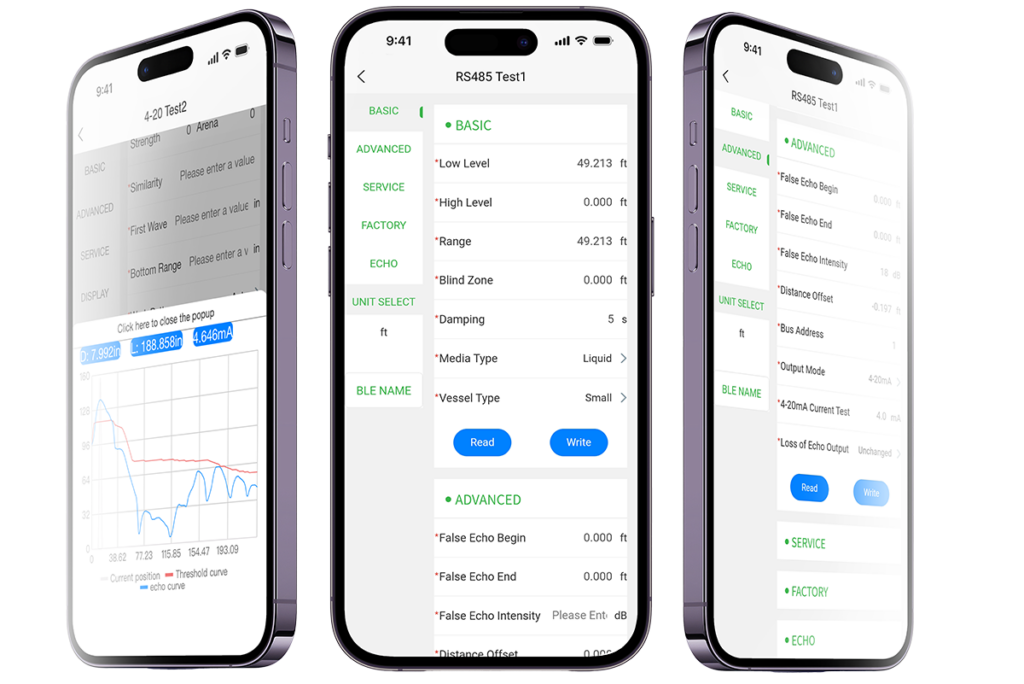

Designed to simplify the setup and optimization of your TRUE ECHO sensors.

Download the App

The TRUE ECHO® CR-L radar sensor ensures precise, reliable liquid level measurement with 80GHz FMCW technology. Its 4º half-angle beam reduces interference and simplifies installation, giving you confidence in your application.

APG offers versatile bracket mounting options for the TRUE ECHO® CR-L radar level sensor, ensuring easy installation across a variety of applications.

Our sales team can help you find the right bracket option to ensure optimal performance and stability for your sensor. Contact us today to discuss your mounting needs and get the perfect solution for your application!

Our product experts are committed to providing exceptional product support to ensure that your experience is top-tier.

Ultrasonic level sensors operate by emitting a burst of sound waves that travel to the target and bounce back to the sensor. It needs an unobstructed air column between the sensor and target. Temperature compensation is used to adjust for the speed of sound in air over the working temperature range.

Radar level sensors utilize electromagnetic waves that travel to the target and bounce back to the sensor. These waves travel much faster and are less affected by temperature. Radar can measure longer distances with more stable results. The radar’s effectiveness depends on the target material’s dielectric constant.

Dielectrics are materials that don’t allow current to flow. They are more often called insulators because they are the exact opposite of conductors. The dielectric constant is a measure of the amount of electric potential energy, in the form of induced polarization that is stored in a given volume of material under the action of an electric field. It is expressed as the ratio of the dielectric permittivity of the material to that of a vacuum or dry air. Here are a few examples of the dielectric constants of different materials. Additional information can be found on the web.

Air = 1.000586

Crude Oil = 2.428

Polyethelyne = 2.3 – 2.4

Water = 80