Surface disruption is a problem in both contact and non-contact methods of liquid level measurement. Stilling wells are an excellent way to dampen these disruptions and provide a clean target surface for an accurate measurement. By isolating a calmer column of liquid, they give your sensor a clean, steady target and eliminate false readings.

At Automation Products Group, Inc. (APG), we’ve helped customers apply stilling wells in everything from wastewater lift stations to food processing tanks. Here’s how they can improve performance, which sensors benefit most, and what to keep in mind during installation.

Why Use a Stilling Well

Even the best sensors can only work with the surface they “see.” In turbulent or foamy conditions, the reading may jump around or become unreliable. A stilling well solves that by:

- Dampening turbulence so ultrasonic sensors get a consistent reflection

- Stabilizing probes and floats that would otherwise bounce or chatter

- Reducing interference from tank walls, piping, or other obstructions

- Improving consistency in applications with constantly agitated or aerated liquid

If your readings look noisy, inconsistent, or erratic, a stilling well is often the simplest and most effective fix.

Sensors that Benefit Most

- Ultrasonic level sensors: Choppy water, foam, or splashing disrupt the echo path. A stilling well calms the surface and provides a reliable reflection

- Level probes: By reducing agitation, probes deliver more consistent data

- Float switches: Instead of riding waves and fluctuating, floats move only with the true liquid level

Quick Tip: With ultrasonics, make sure the inside of the well is smooth—no joints, seams, or ridges that could create false echoes. Also, check where temperature is measured. APG sensors capture temperature at the transducer face inside the well for precise compensation.

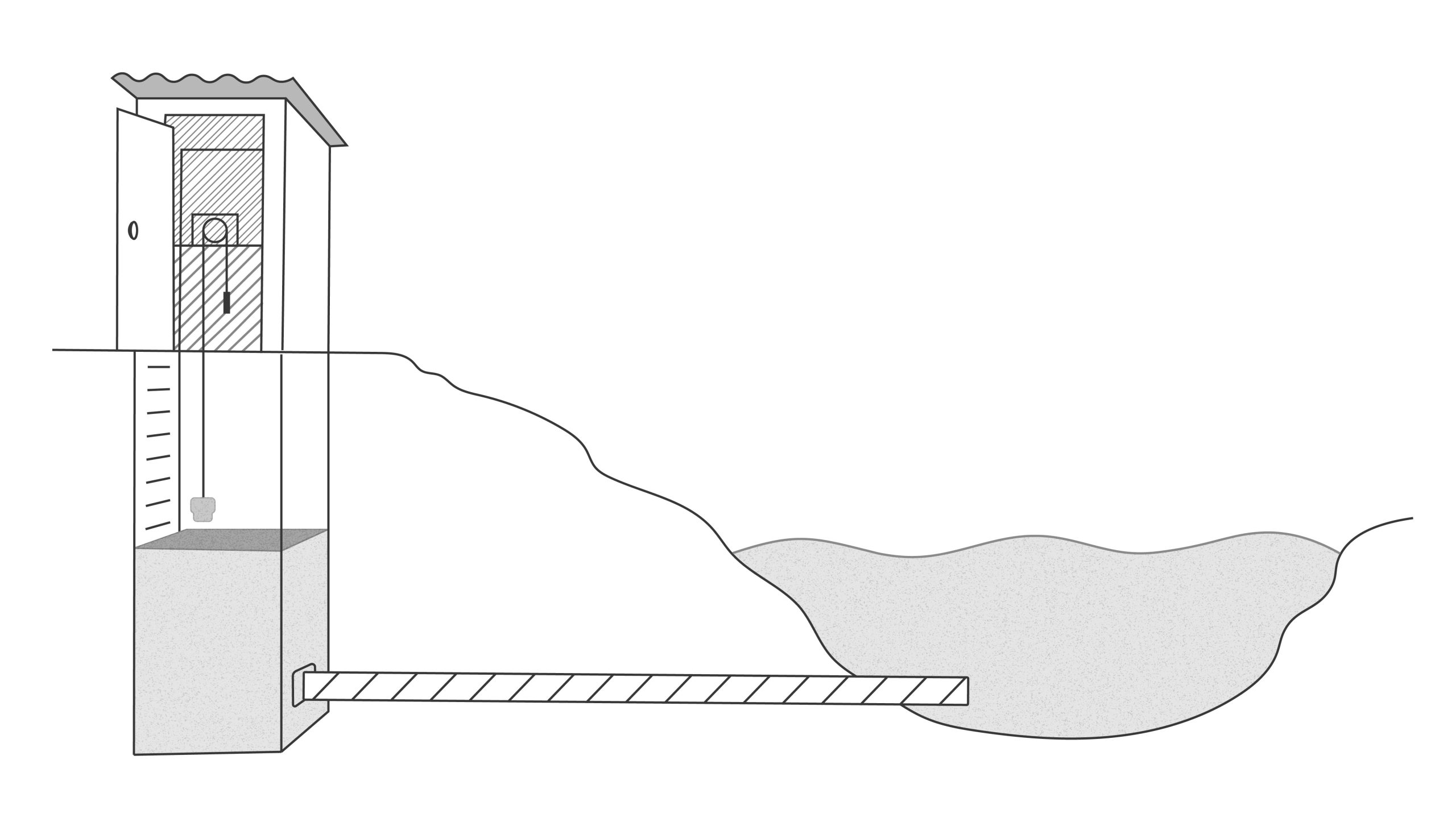

Best Practices for Mounting a Stilling Well

When installed properly, stilling wells are a great way to improve your sensor’s performance, increase accuracy, and tame difficult applications.

- Choose a seamless PVC or steel pipe with the appropriate threaded NPT fitting to mount the ultrasonic sensor. Use a reducer if needed.

- Drill a 1/4” vent hole in the pipe within the blanking distance of the sensor. This allows the liquid to travel up the pipe without pressure building up.

- If the pipe needs to touch the bottom of the tank, drill several ¼” holes in the last few inches so the liquid can enter. You’ll typically need 4 to 6 holes.

- Place the pipe as vertically as possible. Make sure the transducer face is at least the minimum blanking distance away from the maximum height of the liquid.

- Mount the pipe using brackets, metal straps, or the best means possible for your application, to ensure the stilling well will stay in place and not move from the vertical position.

Practical Considerations

Make sure to put a hole in the well above the blanking distance. This lets the fluid move up and down the tube to reflect the true level in the vessel. A stilling well with no hole to equalize pressure at the top captures the air above the liquid and pushes down onto the surface of the liquid.

The stilling well should be as long as the deepest measurement required, with sufficient openings below the deepest level measured to allow the fluid to equalize inside the tube. If the tube touches the bottom, make sure there are holes large enough to allow the liquid to flow freely.

You may need an alternate sensing method if you have an application with the potential for biological growth or deposit accumulation on the stilling well walls.

A stilling well isn’t complicated, but it’s one of the most effective tools you can add to a level measurement system. By taming turbulence and providing a clean measurement surface, it helps ultrasonic sensors, probes, and float switches perform at their best.

If your application is struggling with foam, turbulence, or inconsistent readings, our APG Measurement Experts can help you determine whether a stilling well, or other approach, is the right fit. Contact us today to talk through your application.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.