Editor's note: This is our third post on API 2350, which covers best practices for preventing tank overfills in petroleum facilities. The first post introduces the Buncefield Incident as a major impetus for the creation of API 2350. You can find the second post on mandatory management and operations practices for preventing tank overfills. This third entry looks at tank operation and alarm automation categories. Our final post on API 2350 covers Levels Of Concern within a petroleum storage tank and the necessary alarms at each one.

Last time I mentioned that I would be discussing the risk assessment component of API 2350 this week. But, before I get into the heart of that, we need to first understand the parameters involved in the standard to perform an effective risk assessment.

Last time I mentioned that I would be discussing the risk assessment component of API 2350 this week. But, before I get into the heart of that, we need to first understand the parameters involved in the standard to perform an effective risk assessment.

Before you can start implementing efforts to reduce risk at your facilities, you must first have a good understanding of the existing situation. You need to know the type of instrumentation each tank has, its level of concerns (LOCs), the rate at which the tank empties and fills, and the level of attendance by personnel near each tank.

As part of this, API 2350 requires that each tank be classified according to three category systems described in the standard. The purpose of the categories is to help tank owners and operators to better evaluate their safety needs. They are as follows:

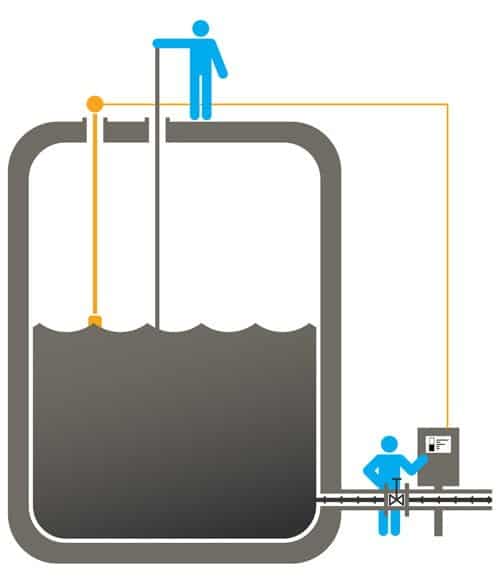

In this configuration, all operations are performed manually by a local operator. Basically this means that an actual person has to be right there by the tank to shut the valve during a receipt in order to prevent an overflow. Also, there are no transmittable alarms or equipment to annunciate alarms. So while there may be tank level gauging equipment installed, it is entirely up to the operator to know when a high level has been reached.

In this configuration, all operations are performed manually by a local operator. Basically this means that an actual person has to be right there by the tank to shut the valve during a receipt in order to prevent an overflow. Also, there are no transmittable alarms or equipment to annunciate alarms. So while there may be tank level gauging equipment installed, it is entirely up to the operator to know when a high level has been reached.

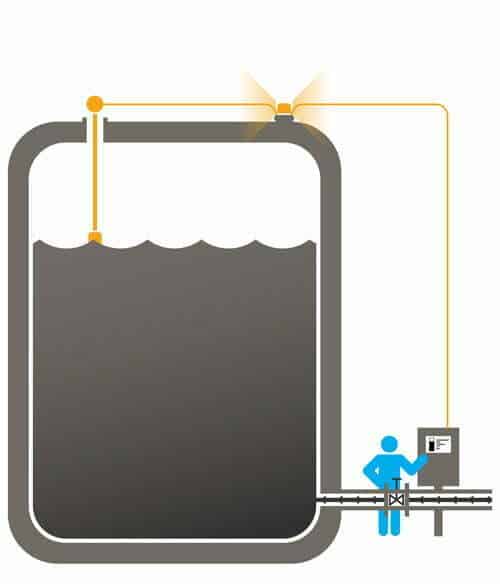

Moving to the next category we can see that the tank is now equipped with sensors and alarms to notify personnel of a high level. Furthermore, shutting off the valve no longer requires an operator to be there right next to the tank. Since the sensors and alarms can transmit the level information, an operator may be able to cancel a receipt by closing the valve remotely from a control room.

Moving to the next category we can see that the tank is now equipped with sensors and alarms to notify personnel of a high level. Furthermore, shutting off the valve no longer requires an operator to be there right next to the tank. Since the sensors and alarms can transmit the level information, an operator may be able to cancel a receipt by closing the valve remotely from a control room.

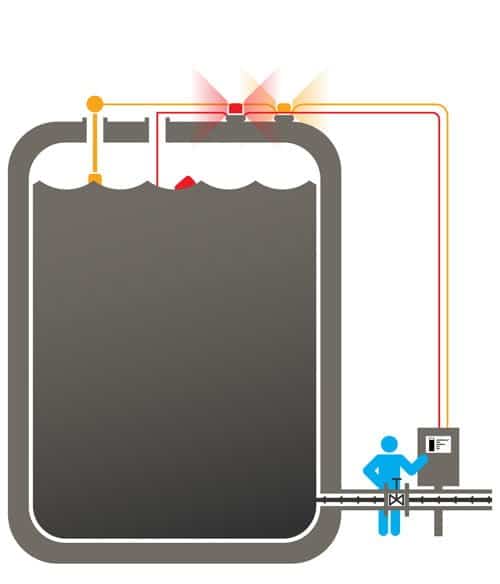

The only difference between this category and the previous one is that a category three tank is equipped with an independent high high level alarm. This category is theoretically more reliant since it has a backup sensor in case the primary one fails. Just like category two the operator may cancel a receipt from a remote location or locally.

The only difference between this category and the previous one is that a category three tank is equipped with an independent high high level alarm. This category is theoretically more reliant since it has a backup sensor in case the primary one fails. Just like category two the operator may cancel a receipt from a remote location or locally.

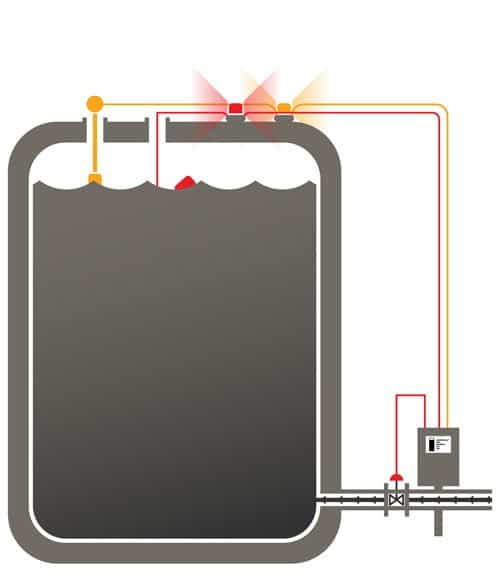

The next category is separate from the first 3 categories. The Automatic Overfill Prevention System is never intended to be used on its own but in addition to one of the other configurations (usually category 2 or 3). Sometimes AOPS is referred to as category four. The advantage to AOPS is that it is capable of executing a shut off without human intervention.

The next category is separate from the first 3 categories. The Automatic Overfill Prevention System is never intended to be used on its own but in addition to one of the other configurations (usually category 2 or 3). Sometimes AOPS is referred to as category four. The advantage to AOPS is that it is capable of executing a shut off without human intervention.

These categories are only part of the parameters that make up the standard. Next week, we will discuss LOCs and attendance level and how these factor into the risk assessment. Let us know if you have any questions on these categories or anything else pertaining to the standard and we will be glad to help.