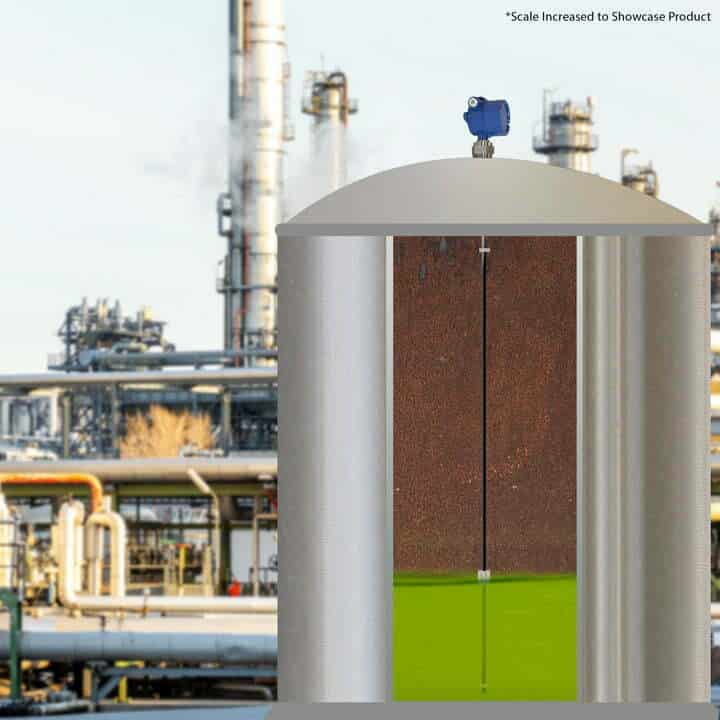

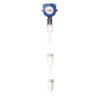

Chemically Resistant Level Transmitter

MPX-E Chemical

PVDF Float and Stem for use in Hostile Chemical Environments

The MPX-E Chemical Level Transmitter is designed with a chemically resistant PVDF float and stem to provide precise level measurements in hostile chemical environments. It is ideal for use in corrosive, acidic, and marine environments, including sulfuric acid, boric acid, hydrochloric acid, and sodium hydroxide. This durable transmitter features Modbus RTU output (RS-485), ensuring compatibility with any Modbus controller or PLC, and simplifying wiring. It also offers compatibility with sensors, and can connect to the Internet with the addition of Settler and Explorer platform.

- Low-Level Fuel-Water Interface Detection: Utilizes high-precision technology to accurately detect minimal fuel and water levels, ensuring reliable interface measurement in tanks and industrial systems.

- Chemical Resistance: PVDF stem and float withstand harsh chemicals like sulfuric acid, boric acid, hydrochloric acid, and sodium hydroxide.

- Modbus Output: RS-485 Modbus RTU for easy integration with Modbus controllers or PLCs.

- Remote Monitoring Compatibility: Works with Settler and Explorer for remote monitoring capabilities.

- Durable Construction: Built to endure corrosive, acidic, and marine environments.