LPU-2428

Intrinsically Safe Ultrasonic Level Sensor

$0.00

LOE

Web Enabled Ultrasonic Level Sensor and Modbus Controller

$0.00

IRU-5000

Short Range Ultrasonic Level Sensor: 79 Inches

$0.00

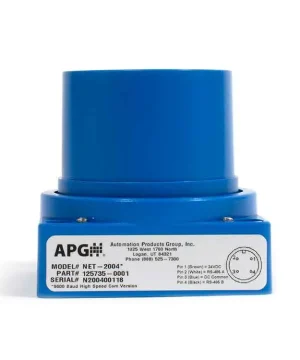

MNU

Modbus Ultrasonic Level Sensor

$0.00

LPU-2127

Loop Powered Ultrasonic Sensor

$0.00

DST

Mid Range Pump Control Ultrasonic Level Sensor

$0.00

IRU-6429

Mid Range Ultrasonic Level Sensor With Data Logging: 30 Feet

$0.00

IRU-2420

Mid Range Ultrasonic Level Sensor: 25 Feet

$0.00

IRU-9400

High Sensitivity Ultrasonic Level Sensor

$0.00

IRU-2000

Object Detection Ultrasonic Sensor

$0.00

MNU-IS

Intrinsically Safe Modbus Ultrasonic Level Sensor

$0.00

IRU-3430

Long Range Ultrasonic Level Sensor

$0.00