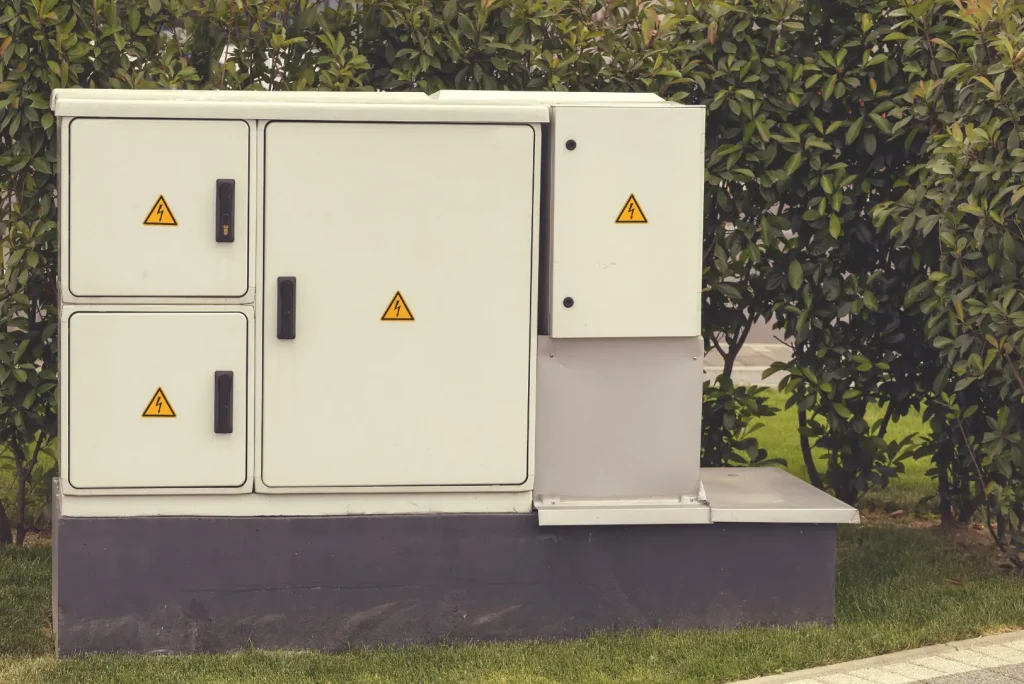

Both NEMA enclosure types and IP ratings types provide protection for electrical components. However, the two different systems vary in the terminology used and the types of protection offered. The conversion chart our experts at Automation Products Group, Inc. (APG) put together below illustrates this.

Review of IP Ratings

An IP rating is specified by the IEC 60529 standard and covers three types of protection. It keeps people from accessing hazardous parts inside the enclosure, prevents the ingress of solid objects, and protects against the ingress of water. IP codes don’t specify protection against ice, oils, coolants, or corrosive agents.

Review of NEMA Enclosure Types

NEMA enclosure types are specified by the NEMA 250. NEMA specifications are less detailed than IP ratings, but cover more types of protection. This includes considerations for construction requirements, door and cover securement, cooling effects, corrosion resistance, effects of icing, gasket aging, and oil resistance.

NEMA vs. IP Ratings: Converting Between the Two

Conversion between IP and NEMA ratings is difficult because they have different vocabulary. Each is more specific in different areas.

With a solid application understanding, conversion can be made without adversely affecting enclosure performance. It depends on the application, and the reasons behind the rating specification. This chart excludes IP code definitions in reference to human access to electrical parts inside the enclosure.

Definitions in the following chart have been paraphrased. Conversions are estimates, and should only be used as a guide. NEMA enclosure types that aren’t specified in the IP code.

| NEMA Enclosure Type | IP Code |

NEMA Definitions |

IP Definitions |

||

| Solids Protection | Liquids Protection | ||||

| 1 | IP10 | For indoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt. | 1 = 50mm in diameter & greater | 0 = Not Protected | |

| 2 | IP11 | For indoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, and dripping/light splashing of liquids. | 1 = 50mm in diameter & greater | 1 = Vertically falling water drops | |

| 3 | IP54 | For either indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, rain, sleet, snow, & windblown dust, & external formation of ice. | 5 = Protected against dust – Limited ingress permitted. | 4 = Water sprayed from all directions – Limited ingress permitted. | |

| 3R | IP14 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, rain, sleet, & snow, & external formation of ice. | 1 = 50mm in diameter & greater | 4 = Water sprayed from all directions – Limited ingress permitted. | |

| 3S | IP54 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, rain, sleet, snow, & windblown dust. External mechanism(s) remain operable when ice laden. | 5 = Protected against dust – Limited ingress permitted. | 4 = Water sprayed from all directions – Limited ingress permitted. | |

| 4 | IP 66 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, windblown dust; rain, sleet, snow, splashing water, hose-directed water; & external formation of ice. | 6 = Totally protected against dust. | 6 = Strong jets of water from all directions – Limited ingress permitted. | |

| 4X | IP66 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt, windblown dust; rain, sleet, snow, splashing water, hose-directed water; corrosion; & external formation of ice. | 6 = Totally protected against dust. | 6 = Strong jets of water from all directions – Limited ingress permitted. | |

| 5 | IP52 | For indoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt; settling airborne dust, lint, fibers, flyings; & dripping/light splashing of liquids. | 5 = Protected against dust – Limited ingress permitted. | 2 = Direct sprays of water up to 15° from the vertical. | |

| 6 | IP67 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt; hose-directed water, occasional temporary submersion at a limited depth; & external formation of ice. | 6 = Totally protected against dust | 7 = Temporary immersion between 15cm & 1m. Duration of test: 30 minutes. | |

| 6P | IP68 | For indoor or outdoor use. Protects personnel from incidental contact with enclosed equipment. Protects from falling dirt; against hose-directed water & prolonged submersion at a limited depth; & external formation of ice. | 6 = Totally protected against dust | 8 = Continuous immersion beyond 1m. | |

| 12 & 12K | IP52 | Enclosures constructed without knockouts for indoor use. Protects personnel from incidental contact with enclosed equipment; Protects from falling dirt, circulating dust, lint, fibers, & flying; & dripping/light splashing of liquids. | 5 = Protected against dust – Limited ingress permitted. | 2 = Direct sprays of water up to 15° from the vertical. | |

| 13 | IP54 | For indoor use. Protects personnel from incidental contact with enclosed equipment. Protects against falling dirt, circulating dust, lint, fibers, & flyings; & spraying, splashing, seepage of water, oil, & noncorrosive coolants. | 5 = Protected against dust – Limited ingress permitted. | 4 = Water sprayed from all directions – Limited ingress permitted. | |

If you have any questions on this chart, NEMA specifications, or IP ratings, contact us today. Our engineers are happy to help answer any of your NEMA vs. IP questions and help you understand how this chart may pertain to your specific application.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.