Editor's note: This is our introduction to the Liquid Level Sensor Technology Decision Tree. You can find the first detailed entry on contact continuous level transmitters here. The second entry, on discrete level switches, can be found here.

Here it is, the week after Christmas, and you still haven’t gotten that special something for your process system. A liquid level sensor would be great, but you just aren’t sure what type of sensor would be best for you, uh, your process system.

Here it is, the week after Christmas, and you still haven’t gotten that special something for your process system. A liquid level sensor would be great, but you just aren’t sure what type of sensor would be best for you, uh, your process system.

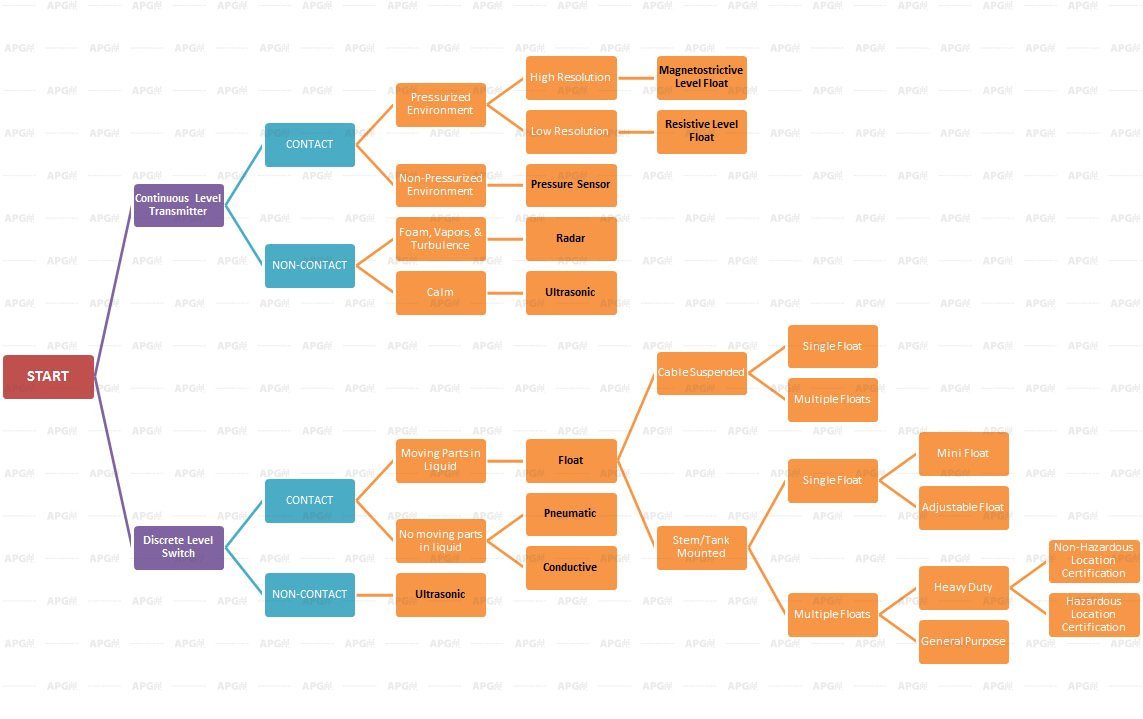

Well, APG is here to help. No, we didn’t put together a comprehensive gift guide for your process system. But, we did manage to assemble this handy-dandy Liquid Level Sensor Decision Tree. Answering each of these questions will help you identify the liquid level sensor technology that best fits the needs of your system.

The chart to the right shows the full range of application questions for determining the liquid level sensor technology best suited to your needs. The main application questions are on purple and teal blocks. Technologies are in black type.

The chart to the right shows the full range of application questions for determining the liquid level sensor technology best suited to your needs. The main application questions are on purple and teal blocks. Technologies are in black type.

The big question to ask for contact continuous level transmitters is whether or not the liquid being measured is pressurized. If the measurements are taken in a non-pressurized area, then a pressure sensor can be used to calculate the level. If the monitored liquid is pressurized, then a float level transmitter will meet your needs.

Ultrasonic sensors and radar sensors are the leading non-contact continuous-level sensor technologies. Ultrasonic works best in situations where foam, vapors, and/or turbulence are either absent or manageable. The frequency and outputs of an ultrasonic sensor can be configured to best fit the physical requirements of the measurement and your existing control and monitoring system. When foam, vapors, or turbulence are not manageable, radar sensors provide more accurate level measurements. As with non-contact level switches, make sure that the facing materials of your sensor are compatible with any vapors or fumes from the liquids being measured.

Most contact level switches are float switches, either suspended from a cable, or mounted on a stem or tank. If your process requires that your sensor have no moving parts in the liquid, then a switch with pneumatic or conductive technology is what you need.

If a non-contact level switch is what you need, an ultrasonic sensor or radar sensor with relay outputs will fit the bill. But, make sure that the material on the face of the transducer or transmitter is compatible with any fumes from your process liquids.

At APG, we offer the sensors and switches, transmitters and transducers to fit almost all of the requirements detailed above. Over the next couple months, we will take a closer look at each of these sections, and how our various families of products can meet your needs. And you can always contact our Measurement Experts by phone, email, or online chat.