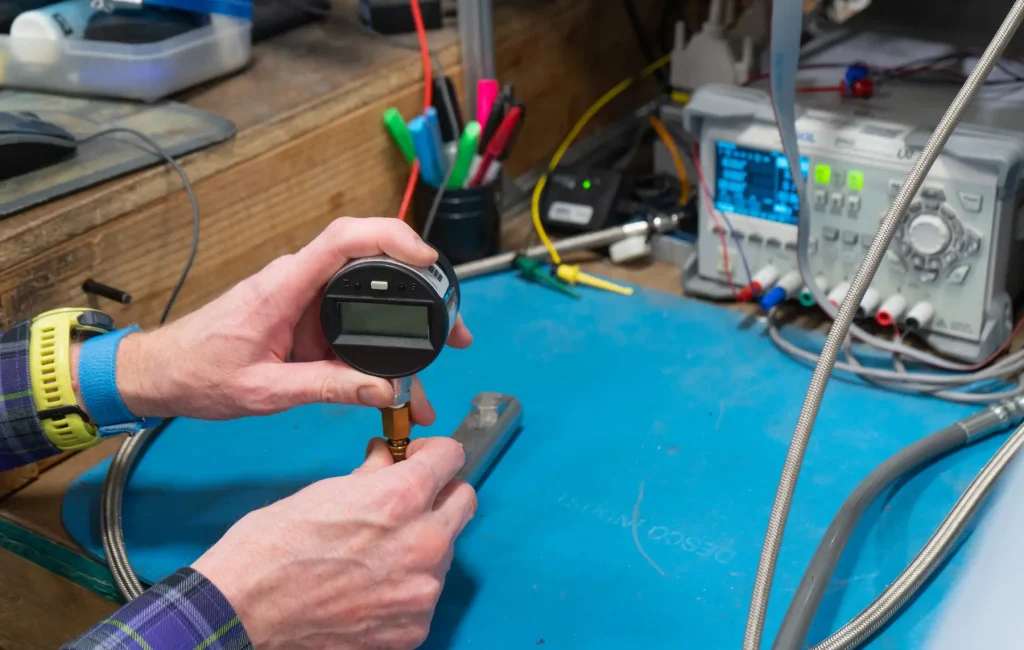

Pressure sensors and gauges need to be calibrated regularly for optimal performance. Calibration depends on the sensor’s measurement and the environment it’s operating in. A typical calibration schedule might be anywhere from once a year to once every three months. The National Institute of Standards and Technology (NIST) is an organization that certifies a sensor’s calibration, and ensures it was performed correctly.

At Automation Products Group, Inc. (APG), we perform NIST certification services for our pressure transducers and digital pressure gauges as often as our customers need. NIST services are important and can keep your operations running smoothly with accurate and calibrated sensors.

About NIST

In 1901, NIST was founded as the first federal physical science research laboratory under the U.S. Department of Commerce. NIST has three core competencies that it focuses on: measurement science, rigorous traceability, and the development and use of standards. Over the years, NIST has made significant contributions that include pollution-control technology, high-speed dental drills, scanning tunneling microscopy, and atomic clocks.

Traceability

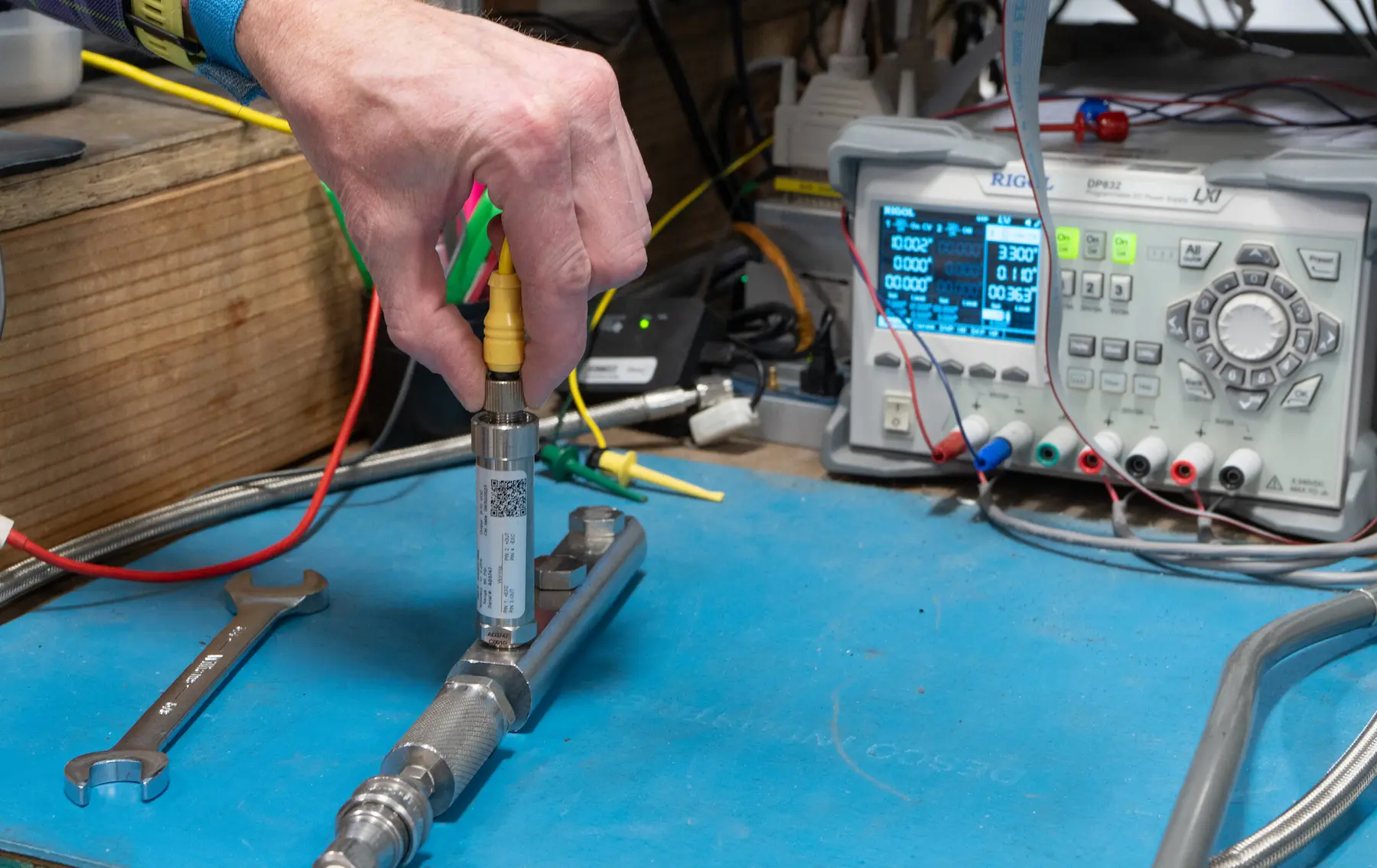

At APG, we provide NIST certification for our pressure gauges and pressure transducers. This process involves submitting the instruments to a pressure calibrator that’s ten times more accurate than the sensors themselves. Every year, we send that pressure calibrator to its manufacturer to have them calibrate it. You can trace the instruments to NIST, who has the ultimate authority on calibration standards.

Recommended Calibration Intervals

So, when should you calibrate your sensor?

Each specific calibration of an instrument depends on several factors. Contract or regulation requirements can complicate calibration, as can the specific accuracy requirements set by the customer. A sensor’s inherent stability or any environmental factors that may affect this stability, also need to be considered. For all these reasons, NIST doesn’t generally require or recommend any set calibration, and instead suggests that organizations implement their own calibration programs to maintain accuracy.

At APG, our calibration recommendation depends on the sensor’s frequency of use. For heavily-used sensors, we recommend calibration at least once every year to keep your sensors reliable and accurate. One of our customers has their sensors calibrated every three months because they have a greater dependence on those instruments to maintain high accuracy. Our calibration process has a quick turn around, so your sensor won’t be gone for very long.

Let us know if you have any questions about NIST certification services, and give us a call if you need to schedule a recalibration. We’ll help you get started with an RMA form. We’re happy to help with any calibration needs you may have!

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.

COLLABORATOR

Karl G.

Karl is APG’s Service & Repair Technician and has been with the company since 2003. In addition to troubleshooting and repairs, he is responsible for renewing the NIST calibrations of APG gauges and transducers, ensuring that customers’ instruments remain accurate and functional for years after they are purchased.