“Is your Shunt Calibration full-scale output or only 80%?”

“Is your Shunt Calibration full-scale output or only 80%?”

There’s a question that will put the brakes on almost any holiday festivities you partake in this month, unless that party is primarily instrumentation engineers and field technicians. Then it might kick the party into overdrive.

But it is an important question. Today we’re going to take a closer look at the two different processes used to produce Shunt Cal, and why more is at stake than just the amount of output each generates.

So, do you know if your Shunt Cal is full-scale or only 80%?

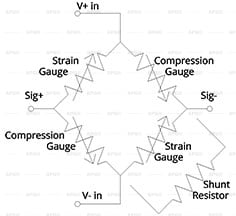

The easiest way to implement Shunt Cal on piezoresistive strain-gauge pressure transducers is to switch in a specifically sized resistor across the Wheatstone bridge of the transducer. Current is shunted through the resistor, driving the output of the gauge to 80% of full-scale output. Why 80%? Because Math.

The easiest way to implement Shunt Cal on piezoresistive strain-gauge pressure transducers is to switch in a specifically sized resistor across the Wheatstone bridge of the transducer. Current is shunted through the resistor, driving the output of the gauge to 80% of full-scale output. Why 80%? Because Math.

This method of Shunt Calibration is quick, relatively easy, and doesn’t significantly increase the cost of manufacturing a sensor. Sizing the resistor is a matter of Math, but after that, the primary hurdle is effectively and efficiently switching the resistor in and out of shunt position.

But moving pieces, especially conductive pieces, right on the gauge is quite a hurdle. Moving parts are more prone to failure than non-moving parts, and placing conductive paths right near the most sensitive electronic part of the sensor is almost asking to introduce noise and bias into the measurement signal.

Transducers with signal conditioning circuitry are also used to produce Shunt Cal. As part of the conditioning, an ancillary circuit can be added that produces a full-scale output. How that is achieved will depend on the design of the signal conditioning circuitry.

A sensor that uses conditioning circuitry for Shunt Cal will probably cost more than one that uses only a shunt resistor. But the trade-offs are substantial: greater reliability, and a full-scale Shunt Cal, rather than just 80%. Without the moving resistor, a sensor with conditioning Shunt Cal doesn’t have the breakdown concerns or noise and bias issues that a sensor with standard Shunt Cal would have. And full-scale output is always more helpful for calibration than 80% of full-scale.

So which kind of Shunt Cal is in your pressure transducers? You’ll have to check the product literature for your sensor. And if that doesn’t tell you, call your sensor’s manufacturer. There’s a big difference between 80% and 100%.

At APG, our Hammer Union 1502 and 2202/2002 Pressure Transmitters are the only sensors we build with Shunt Calibration. Because of their size and the pressure ranges they handle, Shunt Cal is the only safe way to test a hammer union in the field. And because our hammer unions are used in tough environments, we only use conditioning circuitry with full-scale output for our Shunt Cal.

Have questions about Shunt Cal and your sensors? Our Measurement Experts would be happy to help you find the answers you’re looking for. Give them a call, drop them an email, or live chat with them today.

top photo credit: Windell Oskay via flickr cc