Editor's note: This is our second detailed look at the Liquid Level Sensor Technology Decision Tree. You can find the overview here.

You have liquid in containers, and you must keep track of the liquid in those containers. You already know that liquid level measurements come in two types: continuous measurements that give ongoing feedback about the level of the liquid being measured, and discrete measurements that provide, essentially, a Yes or No answer to the question, "Is the liquid at this particular level?" But which technology type is the right one for you? Your liquids don’t require "up-to-the-minute" monitoring, you just need to know when "critical levels" are reached. Congratulations, you need a float switch!

You have liquid in containers, and you must keep track of the liquid in those containers. You already know that liquid level measurements come in two types: continuous measurements that give ongoing feedback about the level of the liquid being measured, and discrete measurements that provide, essentially, a Yes or No answer to the question, "Is the liquid at this particular level?" But which technology type is the right one for you? Your liquids don’t require "up-to-the-minute" monitoring, you just need to know when "critical levels" are reached. Congratulations, you need a float switch!

Float switches are some of the simplest liquid level sensors. They are simple mechanically, simple electrically, and, quite simply, they just work! Mechanically, a float rising and falling with the level of the liquid does all of the physical work. The float contains either a magnet or a tumbler, which, in turn, opens or closes a reed switch as it goes up and down. And that's the extent of the electrical operation, too. Up and down; off and on. It's simple, and it works.

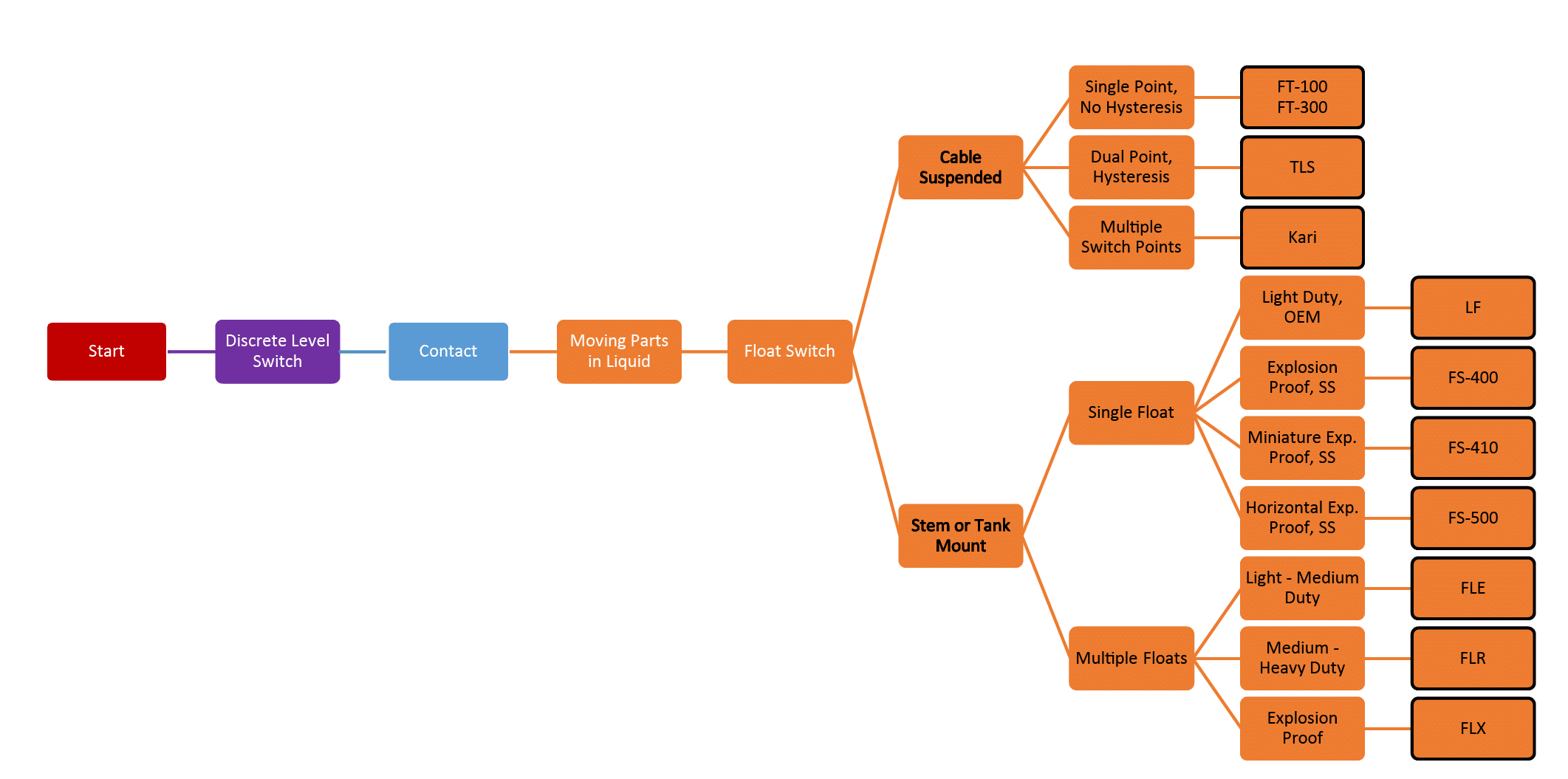

The chart to the right shows the Discrete Level, Contact technologies branch of the Liquid Level Sensor Technology Decision Tree. Main application questions are on purple and teal blocks. Technologies are in bold type. APG product families are at the far right, outlined in black.

The chart to the right shows the Discrete Level, Contact technologies branch of the Liquid Level Sensor Technology Decision Tree. Main application questions are on purple and teal blocks. Technologies are in bold type. APG product families are at the far right, outlined in black.

But don't let the simplicity fool you into thinking that float switches are restricted in their applications. It's their simplicity that makes them so versatile. Float switches can stop and start motors, or provide alarms to signal that motors need to be stopped or started. Float switches can be inputs to PLCs that trigger process-related events, or they can be wired to audio/visual alarms to signal the need for manual intervention. And while most float switches can perform any of these individual tasks, some float switches can do multiple tasks simultaneously!

It's tempting to think that the uniformly simple functionality of float switches is indicative of uniform physical design, but that is not true. Rather, the uniform simplicity allows for a multitude of physical forms, so that application dictates the form of the switch, rather than the physical form of the switch limiting the places it can be used. For small vessels, there are miniature switches. For applications with deeper liquids, there are cable-suspended float switches. Stem-mounted float switches work well in tight, narrow places, and can have up to seven switches on a single stem. No matter the physical situation, there is a float switch that can be made to work.

The one limiting factor for float switches is they must be in contact with the liquid being monitored. Which, to be fair, isn't much of a challenge if your liquid is inert. But if your solution is caustic, corrosive, or otherwise aggressive or nasty, you will need to make sure that the wetted material of the switch is compatible with your liquid. The easiest way to ensure that is to look at the material of your container. If the container can safely restrain the liquid, then a float switch using the same material ought to be safe.

One last feature of float switches: they are easy to wire, to hook up electrically. This is because they only open and close the circuit they are connected to. They don't store voltage or current or energy, they don't amplify or modulate signals of any kind, and they only ever turn on and off. So each switch only needs two wires. The most difficult part of wiring a float switch is making sure that you connect it to the correct part of your control system. Once that is set, you and your float switch are ready!

APG has so many float switches, you are nearly guaranteed to find one that will fit your needs. From single- and dual-point to up-to-four-points cable suspended float switches, to miniature stem-mounted and stainless steel stem-mounted float switches, and our multi-point, heavy duty multi-point, and hazardous location multi-point stem-mounted float switches. Whatever your situation, our Measurement Experts can help you identify the float switch that best fits your needs.

If you have any questions about liquid level sensor technology, float switches, or any of our other products, contact us today.