Pressure sensors and digital pressure gauges are often subject to large fluctuations in temperature which can lead to decreased accuracy. In applications where maintaining high standards of accuracy is a must, this effect can lead to major issues.

Pressure sensors and digital pressure gauges are often subject to large fluctuations in temperature which can lead to decreased accuracy. In applications where maintaining high standards of accuracy is a must, this effect can lead to major issues.

Elden Tolman, an APG engineer, explains that there is virtually nothing that can be done to correct this problem in the field. Your best defense is to choose the right sensor. Therefore, your pre-purchase research is vital:

The first step is to determine the range of temperatures for which the pressure transducer must compensate. This is called the instrument’s compensation range.

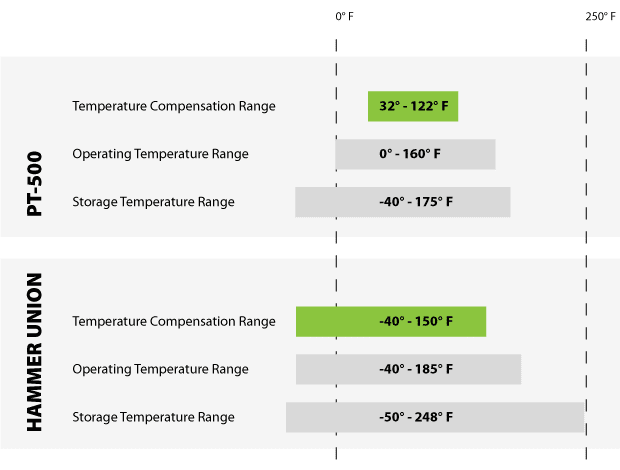

Be sure not to confuse the compensation range with the operating temperature range or storage temperature range:

Different types of sensors and digital gauges are designed to compensate for temperature fluctuations found in their particular applications. Depending on the application that the sensor is designed for, it may require a larger or smaller compensation range.

Different types of sensors and digital gauges are designed to compensate for temperature fluctuations found in their particular applications. Depending on the application that the sensor is designed for, it may require a larger or smaller compensation range.

For example, our submersible pressure transducer, the PT-500, has a temperature compensation range of 32 – 122° F, an operating temperature range of 0 - 160°F, and a storage temperature range of -40 to 175°F. The PT-500 is often used in lift stations where the temperature of the wastewater tends to remain constant. Therefore it does not require a large temperature compensation range.

On the other hand, our hammer union pressure transmitter, which is used in the oil and gas industry for operations such as hydraulic fracturing, requires a larger temperature compensation range of -40 to 150° F. The operating temperature range is -40 to 185°F, and the storage temperature range is -50 to 248°F.

In addition to finding the right compensation range, you must be aware of the sensor’s margin of temperature error.

Manufacturers of pressure sensors and pressure gauges will often include a measurement of temperature error given as a variation of the span and zero. The zero thermal error, or “shift”, is the variation in the signal output while no pressure is being applied. The span thermal error, or “shift”, is the variation in the signal output while full scale (maximum) pressure is applied.

Both of these are often expressed as a percentage when divided by the full scale of the sensor’s measurement range. Here at APG we take it a step further and express it as a percentage of the full scale per degrees Fahrenheit.

Our PT-500 has a temperature error of .025% F.S./°F for both the span and the zero. In other words, for every degree of temperature change, the accuracy can fluctuate as much as .025% of full scale. Adjusting the zero point of the gauge or transducer at the current temperature minimizes thermal shift, but is not always possible – depending on the sensor’s design.

If your application does not involve high fluctuations in temperature, there is one thing you can do on your own in the field to reduce temperature error: Make sure you calibrate your pressure transducer to its zero point while at the normal operating temperature when no pressure is being applied.

Let us know what type of temperature fluctuations you are dealing with and we will help you find which sensor or digital gauge is best for your application.