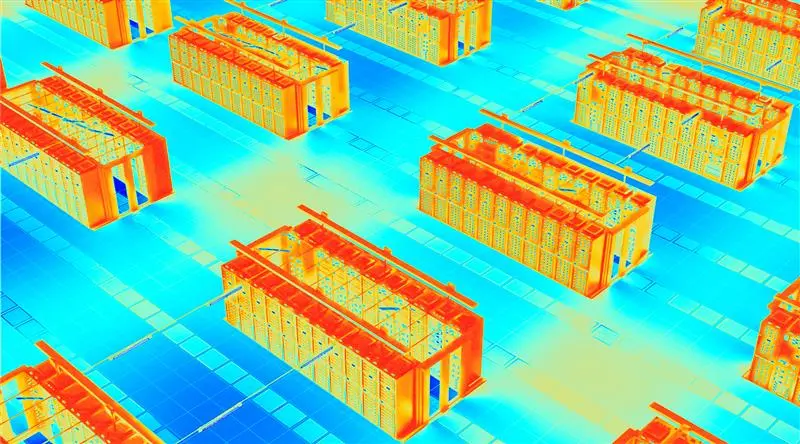

Keeping a data center cool is vital, preventing valuable equipment from overheating and becoming damaged. Hot spots can occur when areas don’t receive efficient cooling.

At Automation Products Group, Inc. (APG), we help engineers and facility managers monitor the systems that keep data centers running efficiently. We’ll explore two common cooling methods, air-cooling systems and liquid cooling systems. Both have their own means of preventing hots spots from occurring.

Air Cooling Systems

Air-cooling has long been the standard used to cool data centers. This method relies on rotating the airflow through hot and cold aisles. Hot aisles extract hot air via cooling units, while cold aisles capture and draw in cool, fresh air. By separating these two aisles, it reduces the risk of mixing hot and cold air. This will prevent hotspots and your equipment from overheating.

However, as AI-driven workloads and high-density racks become more common, traditional air-cooling systems struggle to keep up. The increased heat load makes airflow management more complex and raises the risk of overheating.

Liquid Cooling Systems

For high-density data centers, liquid cooling is preferred over traditional air-cooling systems. The coolant is circulated directly to the heat source via pumps and pipes. Liquid cooling drastically reduces the risk of hot spots, making it the best option for preventing hot spots. Liquid conducts heat more efficiently than air. As the liquid absorbs and transfers heat away from the electronics, it keeps the overall temperature down, further reducing hot spots from forming.

APG Sensors in Data Centers

Reliable cooling depends on knowing what’s happening inside your system at all times. APG’s pressure and level sensors provide real-time insights in coolant performance, helping prevent downtime and optimize system efficiency.

Here’s how APG sensors help:

- Monitor line pressure: Pressure shifts can signal flow issues, leaks, or blockages.

- Verify coolant circulation: Clogging or pressure shift can mean there’s pump issues.

- Measure coolant levels: Ensure the coolant tanks don’t run dry and give alerts when refilling is needed.

Compact and built for demanding environments, APG’s PT Series pressure sensors are ideal for liquid cooling loops, manifolds, and reservoirs, even in tight spaces or corrosive conditions.

Stay Cool with APG

As data centers grow more powerful, so does the need for precise, reliable cooling. With APG sensors, you can stay ahead of hot spots and keep your operations running smoothly.

Looking for a sensor for your data center operations? Contact one of our application experts today to find the right sensor solution for your application.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.