Electromagnetic interference (EMI), also known as electrical noise, can destroy a clean signal from your level sensors and pressure transducers. Protecting your sensors from electrical noise is a top priority. At Automation Products Group, Inc. (APG), we’ve put together four tips to keep EMI at bay. Let’s take a look!

Tip 1: Shielded Wire

Our first critical tip for eliminating EMI is to use shielded wire. This is often overlooked when the budget’s tight or when the risks aren’t understood. Part of this task is making sure the right personnel are installing your instrumentation.

We found one of our sensors installed with standard electrical wire, the kind buildings are wired with. This happened because our customer asked a standard electrician to install the sensors. Instrumentation wiring is a specialty, and may not be well understood by an electrician, especially one whose trade is light fixtures, appliances, and power outlets.

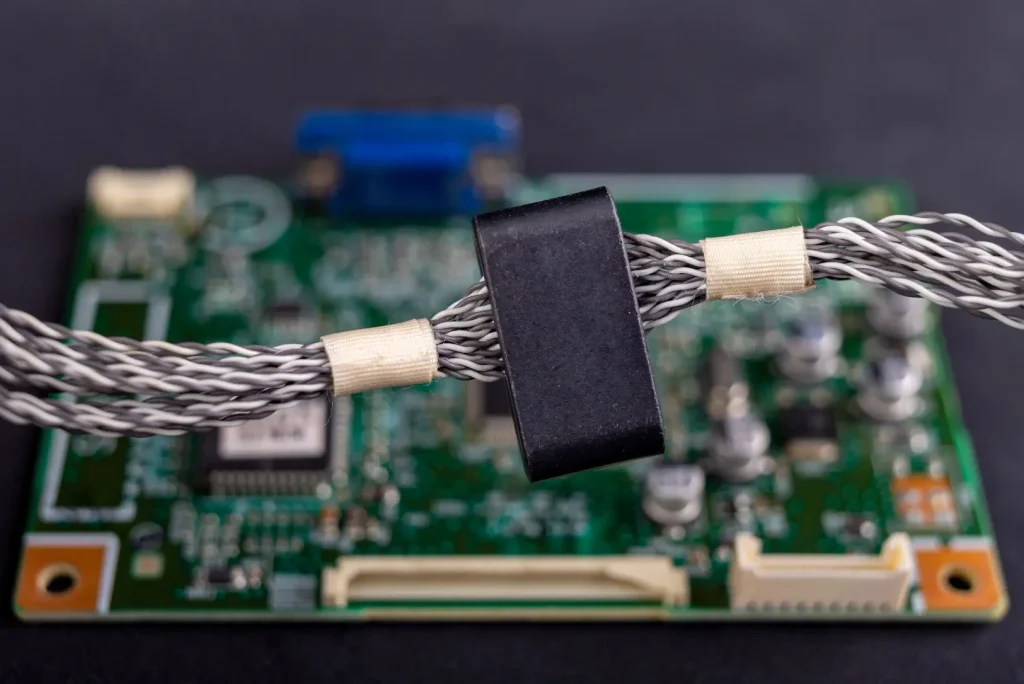

Good wire for instrumentation is usually twisted and shielded, though the specific cable varies depending on the sensor. Make sure you stick to the sensor manufacturer’s recommendations.

Tip 2: Cable Routing

Our second tip for eliminating electrical noise is proper cable routing. Unfortunately, this is often forgotten. The image shows signal cable routed right next to an electrical outlet. This is wrong! Signal cable should be routed away from electrical power cables, power sources, electric motors, and any other electrical fixture.

Our second tip for eliminating electrical noise is proper cable routing. Unfortunately, this is often forgotten. The image shows signal cable routed right next to an electrical outlet. This is wrong! Signal cable should be routed away from electrical power cables, power sources, electric motors, and any other electrical fixture.

Higher voltages increase electrical noise. Electric motors are especially bad, as they produce a magnetic field that causes intense EMI.

How far away do you need to route the cable? That depends on things like voltage and the size of any magnetic field. Even a few inches can make a huge difference. The point: do the best you can to keep them separate. If you notice EMI, then you need to reevaluate and try again.

Tip 3: Proper Grounding

For our third tip to eliminate EMI, you need proper grounding. Your sensors should be connected to a good ground. Avoid ground loops by using a single ground or by ensuring that multiple grounds have the same potential. What does this have to do with EMI? Ground is the path that carries electrical noise away from your signal wires.

The shielded wire should have a good contact with a drain wire, which should be connected to ground. This provides a path for electrical noise to travel to ground, instead of using your signal wire. If the connection to ground is insufficient, the shield will be ineffective. If a ground loop exists, a current will flow through the cable shield and will not stop EMI.

An improper ground is bad. Not only will you be prone to EMI, but you’ll also lose your protection from power surges. In addition, an electrical circuit without a ground increases the risk of shock. Proper grounding should be a top priority.

In contrast, a good ground, proper cable routing, and the right signal cable will stop electromagnetic interference, keeping your measurement signals clean.

Tip 4: Sensor Outputs

If you are still experiencing EMI, note that some outputs are more prone to interference than others. For example, sensors with millivolt output are exposed to EMI due to the low-power output. Sensors with voltage output are better because the signal is amplified.

A milliamp output is the best for EMI avoidance. A 4-20mA signal, for example, is well suited for long distance cable runs because it’s not susceptible to electrical noise and resistance. Unlike voltage output, a milliamp signal has the same strong signal at any point in the circuit.

Ignore any of these four critical tips and the signal from your sensors may be left unprotected. EMI will compromise the integrity of your signal and ruin your ability to measure your key levels and processes.

Follow these important tips to ensure you don’t suffer from EMI. You’re already investing in measurement instrumentation and expecting a certain accuracy rating. Protect that investment with proper cable, smart cable routing, thoughtful grounding, and the right signal outputs.

Let us know if you have any troubles with electrical noise, or any questions as you prepare to avoid it!

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.