Editor's note: This is our first detailed look at the Liquid Level Sensor Technology Decision Tree. You can find the overview here.

Let’s be honest with each other. (It’s ok, we’re all friends here, right?) When you think of continuous liquid level measurement, magnetic float level sensors aren’t the first thing you think of. And when you do think of them, your first instinct isn’t “Hey! That’s the perfect sensor technology for this job!”

Let’s be honest with each other. (It’s ok, we’re all friends here, right?) When you think of continuous liquid level measurement, magnetic float level sensors aren’t the first thing you think of. And when you do think of them, your first instinct isn’t “Hey! That’s the perfect sensor technology for this job!”

It’s ok, you’re not alone. The excuses come easy: too much upfront effort to determine the length of the stem; no idea what kind of float to use; more expensive to transport; difficult to store and install. Yeah, we’ve heard them all.

But notice what doesn’t come to mind: maintenance, ease of use, reliability, and durability. That’s because you don’t have to worry about any of these issues with a magnetic float level sensor. They are simple to use, and highly durable, which translates to incredibly low maintenance and long-lasting reliability. Let’s take a closer look.

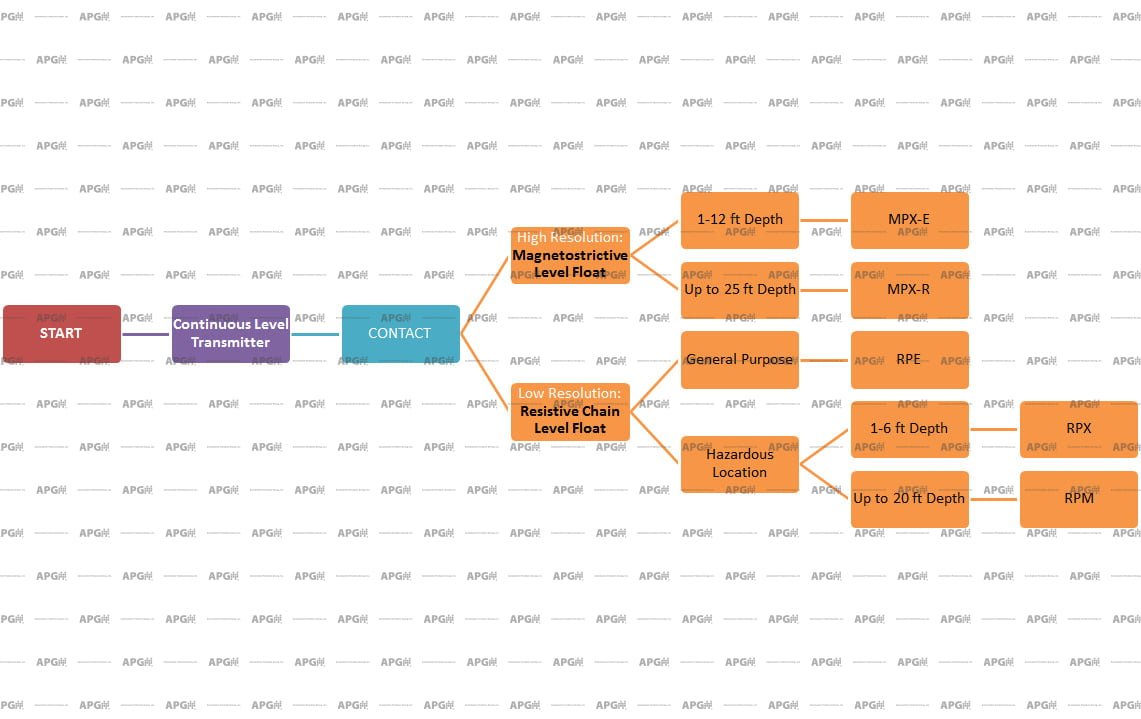

The chart to the right shows the Continuous Level, Contact technologies branch of the Liquid Level Sensor Technology Decision Tree. Main application questions are on purple and teal blocks. Technologies are in bold type. APG product families are at the far right.

The chart to the right shows the Continuous Level, Contact technologies branch of the Liquid Level Sensor Technology Decision Tree. Main application questions are on purple and teal blocks. Technologies are in bold type. APG product families are at the far right.

The technology behind magnetic float level sensors—both magnetostrictive sensors and resistive chain sensors—is simple: when the liquid goes up or down, the float goes up or down. The position of the float on the stem changes the electrical behavior of the circuit in the stem (fancy physics happens here) allowing the controller to calculate the location of the float.

And that’s it. If the float goes up and down, the sensor will work. If you know the viscosity and specific gravity of the liquid you need to measure (and even if you don’t, we can help you find it), we can configure a magnetic float sensor for you. Foam? No problem. Vapors? Doesn’t matter. Exposed to the elements? Don’t worry. None of these factors will affect a magnetic float sensor. It will simply work.

Magnetic float level sensors aren’t just easy to use, they are easy to set up. There’s no setting of empty and full levels and blanking distances, no calibrating response times or pulses and sensitivity, or any of the other fun initialization steps for ultrasonic and radar sensors. You don’t even have to worry about zero and span, like on some pressure transducers. Once your magnetic float level sensor is physically installed, it’s ready to go.

Sure, you can get a magnetic float level sensor with some brain power built in, so it can translate level readings into volume or weight (or even flow!) measurements. But with the other sensors, you still have to go through all rest of the setup to get to that step. Go ahead; take your time. The magnetic float level sensor will wait for you. It’s not in a hurry.

I’ve already said it, but it’s worth repeating: if it floats, it works. Which means the only way to break your magnetic float level sensor is to make it not float. For example:

A local municipality spent a great deal of resources trying a variety of technologies for their hydroelectric dam application. Due to the extremly cold water and hot external temperatures, the temperature gradient caused issues with the ultrasonic sensors they tried. So they moved on to radar. In the winter, icicles would form on the face of the radar sensor causing erratic readings. They spent $3000 + on a sensor that required daily maintenance in order for it to work properly. Finally they tried our MPX sensor. While the water is cold, it constantly moves, so no icicles form down by the float, allowing it to travel up and down without any issue. The $1200 sensor saved the day.

It’s floating, so it’s working.

“Hey, what about stuck floats? If it’s stuck, it can’t float, so it doesn’t work, right?”

Good question. Yes, if a float gets stuck, it can no longer accurately indicate the level of the liquid. But it just doesn’t happen very often. One of our Measurement Experts, who has been with APG for more than five years, cannot recall a single instance of a customer calling with a stuck float. Five plus years, no stuck floats. That, folks, is reliability.

APG offers two types of magnetic float level sensors: the high resolution magnetostrictive MPX, and the lower resolution resistive chain RP/RPM. The stem lengths, float materials, and CSA approvals vary across both families. But expert workmanship and long-lasting reliability come standard with every sensor. Ask our Measurement Experts how a magnetic float level sensor can improve the reliability and simplicity of your level measurements.