With several forms of measurement technology on the market, it can be hard to decide on which sensor is the best for your application. At Automation Products Group, Inc. (APG), our team works closely with engineers and operators every day to select reliable sensing solutions. This guide compares radar level sensors and submersible pressure sensors to help you make an informed, confident decision.

Submersible Pressure Sensors

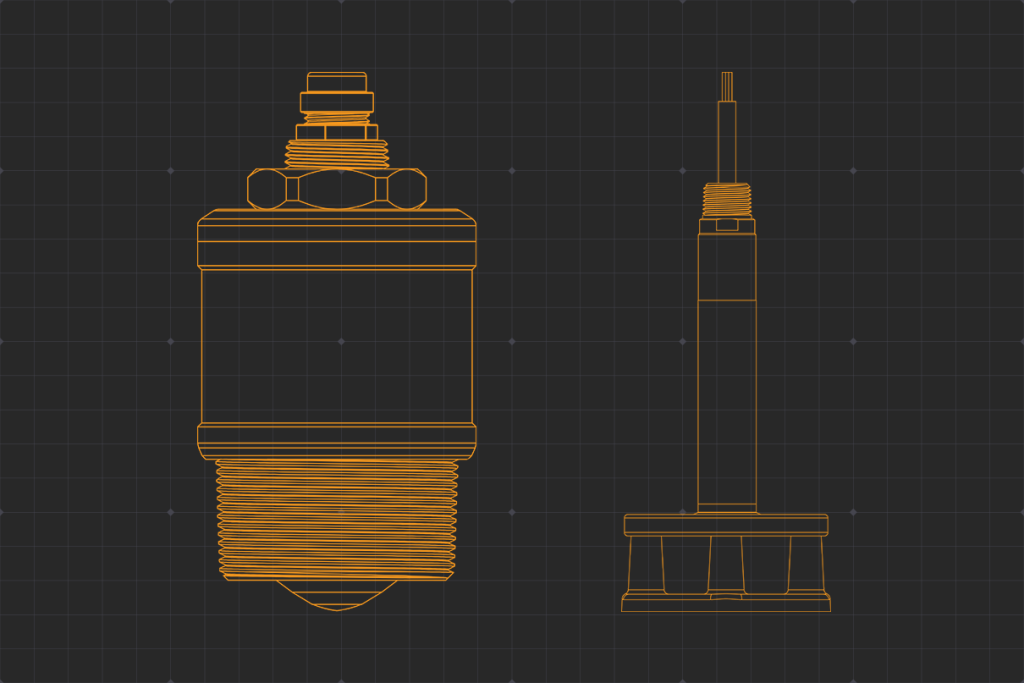

Submersible pressure sensors are installed directly in the liquid they’re measuring, typically resting at the bottom of a tank, well, or basin. The liquid pressure is directly proportional to the liquid’s density and height. As the level increases, so does the pressure on the sensor diaphragm, generating an electrical signal that is converted into a level reading.

Along with measuring the liquid level, submersible pressure sensors can also measure both the water pressure and temperature, making them a versatile solution for many applications. Their position at the bottom of the liquid means that they don’t get interference from foam or turbulence at the water’s surface. With submersibles, you must make sure that the housing and sealings are compatible with the liquid being measured. Submersibles are ideal for liquids but cannot measure solids.

APG offers several proven submersible pressure sensors to match a wide range of applications:

- The PT-500: Has options for both clean liquids, and a caged version for dirty liquids

- The PT-500E: NSF-certified for potable water applications.

- The PT-503: Constructed out of durable PVDF materials for excellent compatibility in harsh chemical environments.

Radar Sensors

Radar level sensors are ideal when contact with the material being measured would damage the sensor, or when non-contact measurement is required. In liquid level measurement applications, radar sensors are typically mounted above the surface of the material.

By using electromagnetic waves, these sensors can detect how much material is present. When the sensor emits waves toward the target’s surface, it times how long the signal’s reflection from the target takes to return to the sensor and converts that travel time into distance. Since these waves travel at a relatively constant speed, it makes radar sensors incredibly accurate.

Some radar sensors can also be used to measure solids. They provide precise level measurements for difficult-to-measure solids, such as powders, pellets, grains, and granules.

APG offers a lineup of several radar sensors for you to choose from:

- TRUE ECHO® CR-L give continuous, high-resolution readings.

- TRUE ECHO Plus combines radar accuracy with pressure measurements.

- TRUE ECHO PRS provides readings for solids.

- TRUE ECHO PRL offers liquid level measurements.

- TRUE ECHO PRX delivers accurate readings in hazardous conditions.

Comparing Radar and Submersible Pressure Sensors

When choosing between radar and submersible pressure sensors, asking the right questions upfront can save time and prevent costly issues later.

How do I want to install this sensor? Submersible pressure sensors are typically quick and simple to deploy, while radar sensors require proper mounting and setup above the process. What is the application environment? Submersible pressure sensors perform exceptionally well in deep liquid applications—up to 250 feet. Radar level sensors are preferred for shallower applications or where non-contact measurement is required.

A Unique Combination

Looking for the best of both technologies? The TRUE ECHO Plus combines a radar level sensor with a built-in submersible pressure sensor inside a single housing. This dual-measurement approach allows for overfill or flood detection, making it ideal for applications where redundancy and safety are critical. Both radar and submersible pressure sensors offer reliable, accurate level measurement. The right choice depends on your process conditions, preferences, and performance requirements.

Not sure which sensor technology would be best for your application? Talk with an APG sensor expert today to get application-specific guidance, trusted recommendations, and long-term support.

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.