Calibration is a critical aspect of pressure sensors, and that includes submersible pressure sensors. Regular calibration of your sensor will help maintain accurate pressure measurements and reduce the risk of the calibration shifting. At Automation Products Group, Inc. (APG), we offer the PT-500 Submersible Pressure Transducer, the only pressure sensor on the market that can be recalibrated in the field. In this guide, we’ll talk about why it’s important to calibrate your sensor, calibration shift, and how to calibrate your sensor.

Why is Calibration Important?

Calibration ensures that your pressure sensor is giving accurate and reliable readings. If there’s a change in the reading from the pressure sensor, but the pressure hasn’t changed, the pressure sensor will need calibration to restore it to its original readings.

Calibration Shift

A shift in calibration for your PT-500 submersible pressure transducer can lead to inaccurate measurements, which aren’t ideal. Since these submersible pressure transducers are commonly used in water and wastewater applications, an error in the sensor’s calibration can lead to all sorts of problems, such as flood risks and tank overflow. There are many factors that cause shifts in the calibration of a pressure sensor:

- Temperature changes.

- Vibration and stress.

- Age of the sensor.

- Environmental factors, such as dust, humidity, and chemical exposure.

- Electrical noise and interference.

When these factors affect your pressure sensor’s calibration, it’s generally ideal to send the sensor back to the manufacturer for service. However, when you take into consideration the downtime spent with the sensor being sent for calibration, and the cost to send the sensor in, the process for recalibration is more complicated and expensive than it appears. By adjusting the PT-500 submersible pressure transducer in the field, you can fine tune the zero point as needed for your application, without the expense and lost time of sending the sensor out for calibration.

How to Calibrate Your Submersible Pressure Transducer

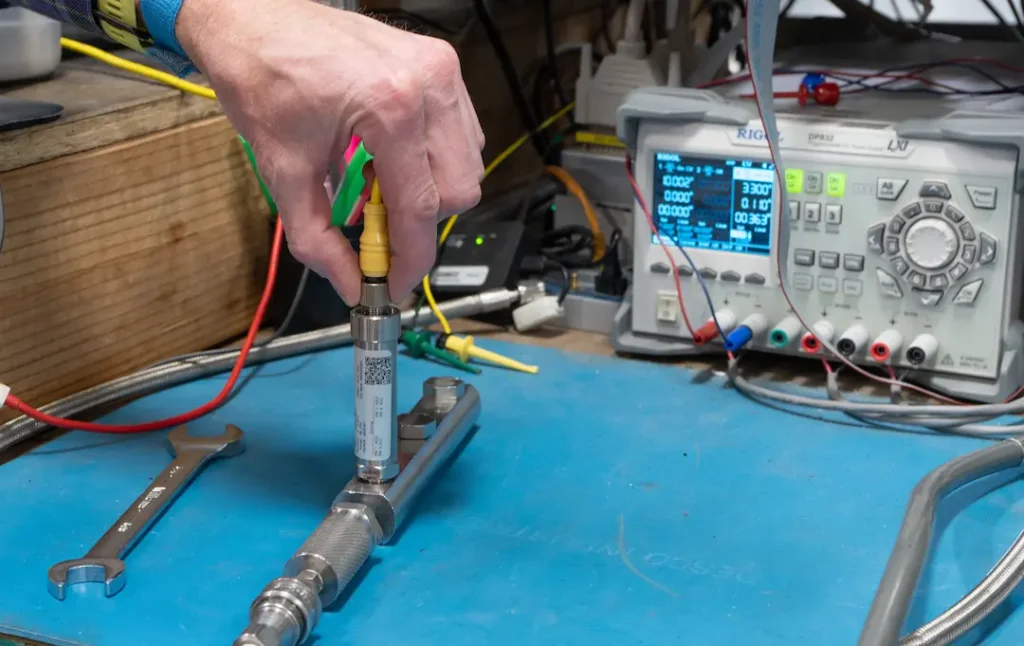

Calibration involves two key reference points: the zero and the span. Many of the issues resulting from the factors listed above can be resolved by resetting your zero point (4mA). The PT-500 submersible pressure transducer lets you do this in the field, without removing your sensor from its setup and sending it out for calibration. The key to this calibration involves the use of a simple magnet.

The zero point can be adjusted by holding a magnet close to the can, about 1 ½ inches from the top or bottom of the can. It can be adjusted ±1 mA, or from 3 to 5 mA.

Holding the magnet perpendicular near the top increases the output.

Holding the magnet perpendicular near the bottom decreases the output.

If the zero output values don’t change right away, follow the steps below:

- Hold the magnet in place near the top of the can until the values change, up to two minutes.

- If there’s no change, repeat the procedure near the bottom of the can.

- If there’s still no change, consult APG for further instructions.

Do note that the calibration of the span must be performed at APG’s factory.

If you need more help with calibrating your submersible pressure transducer, please feel free to reach out to us. Our experts are ready to assist you in your calibration needs!

WRITTEN BY

Sami T.

Sami Thompson is APG’s Marketing Technical Writer and has been with the company since 2022. With a master’s degree in English from Utah State University and a 40-page thesis publication under her belt, Sami has a demonstrated strong writing background. In her free time, Sami enjoys reading and birdwatching.